Get Top-Quality, Custom Aluminum Die-Casting Parts Quickly

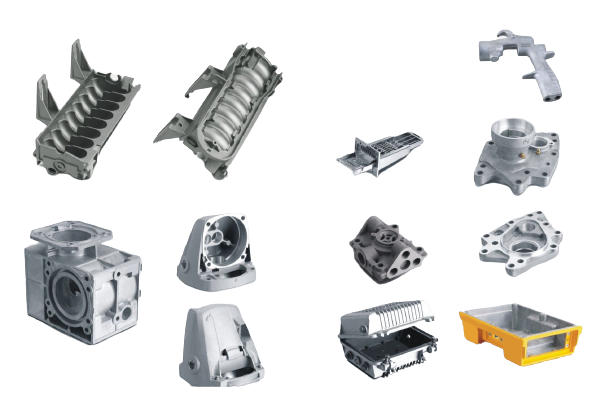

We provide high-precision aluminum die casting solutions with fast turnaround times and exceptional customer service. Whether you’re looking for complex parts or simple solutions, we can meet your specific needs at competitive prices.

As a Leading Aluminum Die-Casting Manufacturer in China, We Deliver on Quality, Speed, and Service

At Cixi Aida Metal, we manage the entire production process in-house to ensure a smooth and efficient experience for every customer. Our skilled team ensures high-quality, fast production to meet your unique specifications. Reach out today for a free quote on your next aluminum die-casting project!

Our Services

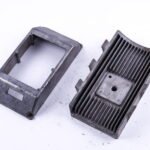

We design and manufacture custom molds with high precision to ensure the efficiency of mass production for your aluminum parts. Our team of expert engineers uses advanced technology to create molds tailored to your needs.

Our aluminum die-casting services ensure the creation of complex shapes with high precision. We specialize in custom die casting for various industries, ensuring that your aluminum parts meet exact specifications.

We provide expert CNC machining services for a variety of materials and complex parts. Our services are perfect for rapid prototyping and low-volume manufacturing, with high precision.

Enhance your aluminum products with our wide range of surface treatment options. We offer anodizing, painting, and powder coating to help customize the final product to match your brand.

Why Choose Us?

Finding a reliable, high-quality aluminum die casting partner can be challenging. At Cixi Aida Metal, we go above and beyond to provide customizable solutions for your unique needs. Whether you’re in need of medical equipment, automotive parts, or LED heat sinks, we are the partner you can trust.

Having gained 20+ years of experience in the industry, there’s little we don’t know about excellent aluminum die casting production. Our factory, based in China, offers the scope to produce fully machined, finished and tested aluminum casting parts.

With a passionate team of over 80 staff members, including sales associates and technicians, the entire production process runs seamlessly from start to finish.

The usual inspection tool is the caliper, but for high precision products we use more advanced equipment

CMM

X-RAY

X-Y-Z

Contact our team today