Die casting is a manufacturing process that involves forcing molten metal under high pressure into a mold cavity. The die casting machine is the equipment used to perform this process. There are several different types of die casting machines, each with its own advantages and disadvantages. In this blog post, we will introduce you to the high pressure aluminum die Casting machine. We will discuss the different types, how to differentiate them, their advantages and disadvantages!

1. What is high pressure aluminum die casting machine ?

The high pressure die casting machine is die casting equipment ,the casting process of using high pressure to quickly squeeze the metal liquid into the die cavity

. Under high pressure and speed, the liquid metal can fill the entire die cavity in a very short time.

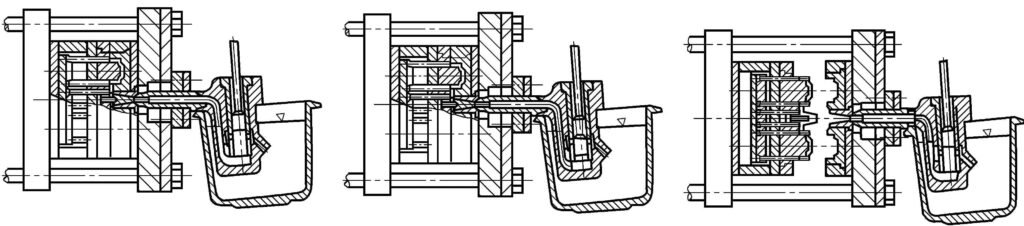

a) types of high pressure aluminum die casting machine

There are two types of high pressures die casting machines: cold chamber machines, hot chamber machines,

b). How to differentiate those two types ?

the differentiated based on the method of injecting molten metal into the die.

In a hot chamber die casting machine, the metal is melted in a crucible and then poured into a chamber where it is injected into the die. In contrast,

The cold chamber die casting machine has a separate melting pot that is not directly connected to the injection chamber.

In die casting, the liquid metal is removed from the holding furnace and poured into the press chamber and then die cast

2. How it works(casting precesses) ?

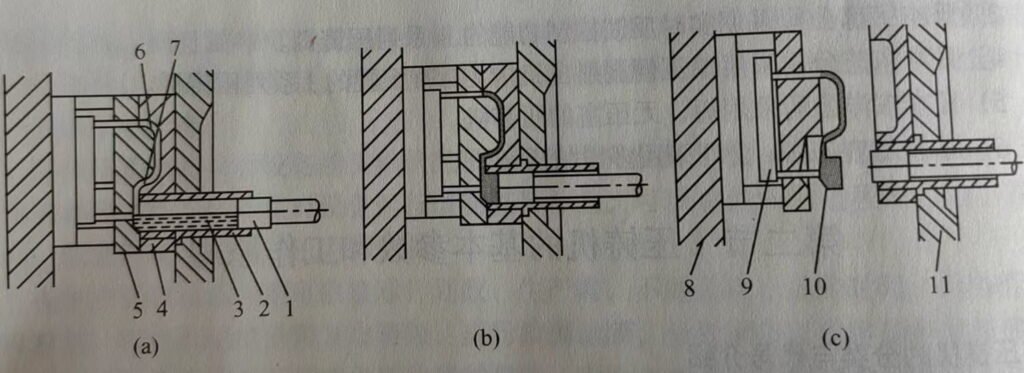

1)Hot chamber

Step1:When the press injection punch is in the up position, the liquid metal in the crucible enters the press chamber through the inlet port.

Step2: After closing the mould, the liquid metal flows into the mould cavity as the pressurised punch is pressed down.

Step3: After solidification, the press punch rises and the excess metal flows back into the press chamber, the mould is opened and the casting removed.

2)Cold chamber

step1: The pressurized punch pushes the metal fluid at a slow speed to fill the front of the press chamber and accumulate at the front of the inner gate.

Step2: The rapid movement of the pressurised punch allows the liquid to fill the cavity high speed through the sprue.

Step3: In the final press stage, the pressurised punch continues to move, compacting the metal, with the speed of the punch gradually increasing.

3. applications of hot chamber and cold chamber

1)Hot chamber

Die casting of low melting point alloys such as lead, tin, zinc and small magnesium alloys

2)Cold Chamber

Aluminium, magnesium, copper non-ferrous and ferrous metals,

So we usually use cold chamber for aluminum die casting parts,

4. Disadvantages and advantages of hot and cold chamber

a)Advantages of hot chamber

*Simple structure and easy operation

*Simple work sequences, high production efficiency

*Low heat loss, low metal consumption

*Clean metal entering the cavity, good casting quality

b) Disadvantages of hot chamber

*Small compression ratio

*Only low melting point alloys can be die cast

*Chamber and punch prone to failure and inconvenient replacement

c) Advantages of Cold chamber

*High specific pressure for dense castings

*Ability to die-cast alloys with high melting points

*Ability to die-cast larger castings

d) Disadvantages of hot chamber

*High heat loss

*More difficult to operate

*Lower production efficiency

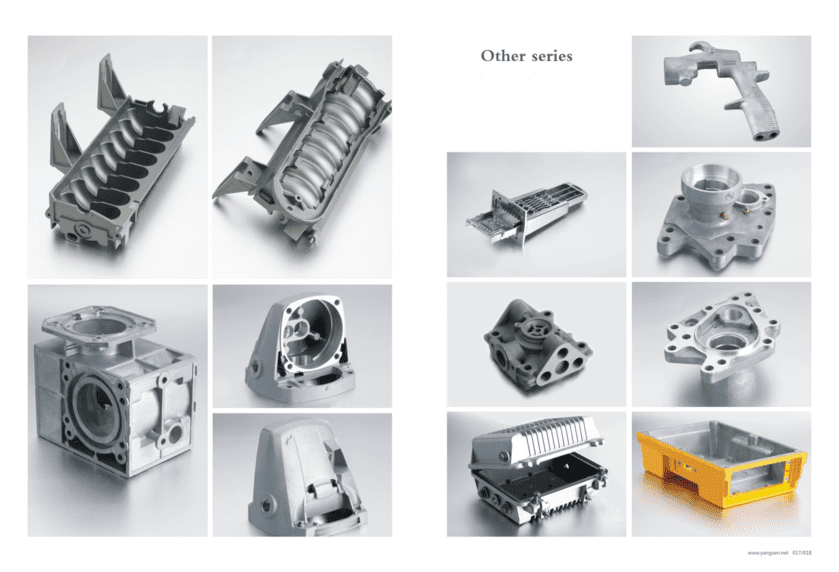

5. Applications of high pressure aluminum die casting machine

High pressure aluminum die casting is so improtant now , there have so many die casting parts manufacturers , most of them are ono-stop serivice , die casting , cnc machining ,surface treatment .

Aluminum die casting has been widely used in various industries, such as:

*Automotive industry: automotive parts, motorcycle parts, engine parts, etc.

*Electronics industry: camera housings, computer housings, electrical connectors, etc.

*Furniture industry: chair legs, table bases, door handles,and so on

6 how to choose high pressure die casting machine

For aluminium alloys, copper alloy castings and large magnesium alloy castings the cold chamber die casting machines is the main choice

For zinc alloy castings and small magnesium alloy castings a hot chamber die casting machines is usually used

7 Some high pressure die casting machine factories

1)Itay

- Itapresse

- Idra

- Colosio

- MGP

2) Germany

- Oskar Frech

- Matal-Guss

3) Canada

- Techmire

- TCS presses

4) American

- Prince

- HPM

- Micromatic

- Operations

- S.M.T

- Nationam Diecasting

- Machinery

- American

5) Japan

- TOSHIBA

- Toyo Machinery

- UBE Kogyo