What are aluminum alloys?

Aluminum alloys are materials with varied compositions and are widely used in different segments of the industry, civil construction, and domestic and professional environments. Aluminum is an outstanding element and, therefore, its properties are noticeable in the products where the alloy is inserted.

Next, we will learn about the main types of aluminum alloys, their advantages, and indications for use. Keep reading and learn more.

What are metallic alloys?

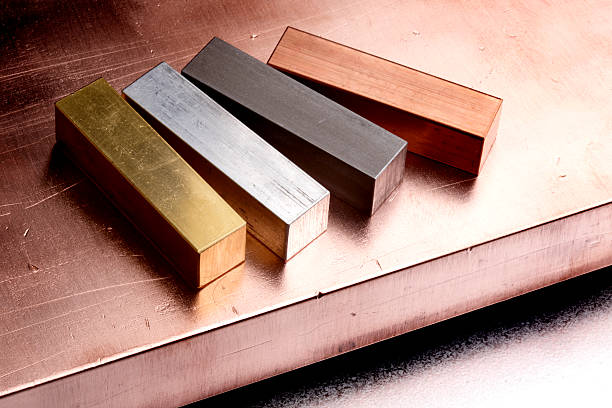

Metallic alloys are mixtures involving two or more substances in which at least one of the components is a metallic element. In addition, he is the one that is found in greater quantity in this junction.

Metal alloys are used to confer or change properties necessary for the most diverse purposes of use.

Features of aluminum alloys

Aluminum is a light, versatile and resistant material, in addition to being very useful. This type of metal is obtained through the electrolytic reduction of alumina dissolved in liquid cryolite.

In the past, aluminum was used to fix objects and as a main component of household utensils and mirrors. Today, we find metal in various types of packaging, in the manufacture of objects, in electrical components, in civil construction, in the automobile industry, and much more.

Aluminum alloys are a subgroup of metallic alloys whose main function is to guarantee more mechanical resistance to the products where they are used, without disturbing the other properties of the material.

In this type of alloy, the component that exists in greater quantity is aluminum. In some cases, it can be composed exclusively of this element, reaching a purity equivalent to 99%.

After casting, the aluminum alloy acquires specific properties, typical of the elements used. It gains greater thermal and electrical conductivity, in addition to brightness and resistance.

Types of aluminum alloys

Aluminum alloys can be divided into two distinct groups: worked and cast. Let’s find out more about them:

Wrought aluminum alloys

The processed aluminum alloys undergo several mechanical processes, such as extrusion, lamination, stretching, and forging.

Its nomenclature is made using four letters X (XXXX) and each letter has a meaning. Check it out:

- 1st X – indicates the alloy series, according to the element that exists in greater quantity. Number 1 represents aluminum;

- 2nd X – if it equals 0, it indicates a normal league. If it is equal to 1, 2, or 3, it is a variation of the normal league;

- 3rd and 4th X – serve to distinguish the many existing leagues.

An aluminum alloy with a purity of 99%, for example, has the following nomenclature: 1099.

Further, aluminum alloys are divided into:

- Heat-treatable wrought alloys: acquire excellent mechanical properties after treatment.

- Non-treatable or hardenable wrought alloys: do not respond to heat treatment. Therefore, its mechanical properties vary according to the degree of cold work or hardening.

Cast aluminum alloys

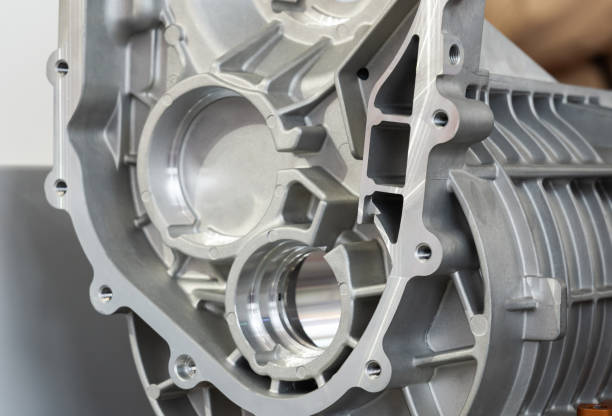

Cast aluminum alloys need to go through the casting process. Only in this way do they acquire the properties desired by the professional who will use them.

The nomenclature of this type of alloy also follows a sequence of four letters X, but with the last one highlighted: XXX.X. The classification is specified as follows:

- 1st X – defines the product series according to the element that exists in greater quantity;

- 2nd and 3rd X – identify alloys with specific compositions;

- 4th X – when equal to 0, indicates that the alloy is ideal for making castings. If it is equal to 1, the indication is for creating ingots.

Advantages of aluminum alloys

The popularity of aluminum has its reasons and preference also comes to aluminum alloys, which have a predominance of this element. Now let’s get to know some of its many advantages:

High thermal and electrical conductivity

Aluminum alloys have an excellent ability to conduct heat. Therefore, they are used in kitchen utensils and other items that require an easy circulation of energy and temperature.

Oxidation resistant

Aluminum alloys are resistant to corrosion, a feature that becomes even more pronounced when this material undergoes treatments that strengthen its properties.

High shine

Aluminum is a material that has a high gloss, reflective surface. For this reason, it was used for many years in decorative pieces. Until today, this advantage makes aluminum alloys implanted in objects with great aesthetic value, such as household items, decoration pieces, and others.

Nontoxic

Aluminum is a non-toxic material. Therefore, it can be used in household items, food packaging, pharmaceuticals, and other products without harming the health of the consumer.

Recyclable

Aluminum is an easily recyclable product, which helps in the regular disposal of items that would go to waste, but which can become a source of income for recyclers, an important feature for the environment.

Application of aluminum alloys

Versatility is also a feature and advantage of aluminum alloys. The material, and its many configurations, can be used in different situations.

Let’s get to know the main applications of the product:

- Household items: stoves, pans, cutlery, appliances, bottles, etc.

- Pharmaceutical industry: especially in the packaging of medicines;

- Food industry: food packaging, soda cans, yogurt caps, and other products;

- Automotive industry: bodies, license plates, fuel tanks, wagons, vehicles, and parts in general;

- Civil Construction: the creation of architectural units;

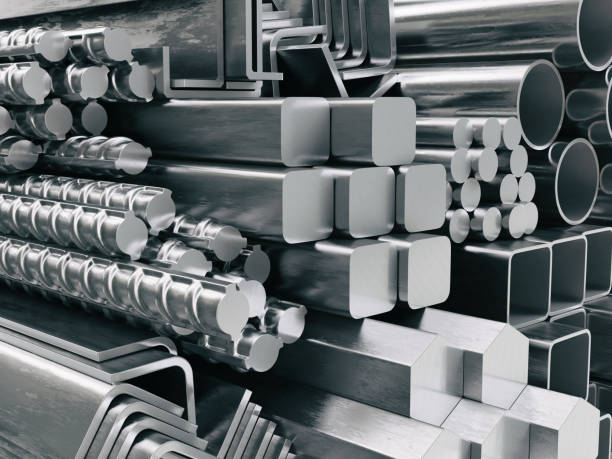

- Ironwork: aluminum alloys are present in plates, metal sheets, and welded structures;

Aluminum alloys are also used in the petroleum, chemical, electrical, aeronautical, and nautical industries and many others.

Aluminum alloys have a series of attractions, which make them material with great and varied use in numerous sectors. Resistant, malleable, a good conductor of heat and energy, economical, sustainable, and aesthetically pleasing, aluminum has multiple applications.