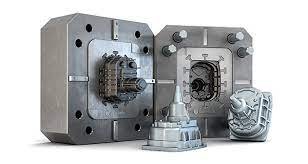

Aluminum gravity die-casting is a common casting technology utilized by various sectors, particularly aerospace, automotive, electrical, healthcare, defense, and recreational equipment. It involves pouring molten aluminum into a mold while tilting it to let the metal fill the cavity and solidify into a casting.

In this article, we will look at the process, benefits, applications, and comparison to other casting methods of aluminum gravity casting.

What Is Aluminum Gravity Die Casting?

has been practiced for many years. It is a procedure where molten aluminum is poured into a gravity mold while being pulled downward by gravity. As the molten metal solidifies, it forms a casting by filling the chamber of the gravity mold. Many sectors use this casting technique frequently because it is accurate, precise, and economical.

Advantages of Aluminum Gravity Casting

Gravity casting is superior to alternative casting techniques in a number of ways. The following are a few advantages:

High precision and accuracy: High accuracy and precision are provided by aluminum gravity casting during the casting process. A casting with excellent dimensional precision is produced by evenly filling the mold cavity with molten aluminum.

Excellent surface finish: Aluminum gravity casting provides castings with a smooth surface finish. The casting’s surface is flawless and free of flaws, making it appropriate for uses that call for a high-quality surface finish.

limited porosity: Low porosity castings made from aluminum gravity casting are produced. Low porosity castings are produced as a result of the molten aluminum evenly filling the mold cavity.

High ratio of strength to weight: High strength-to-weight ratio castings are produced by gravity-casting aluminum. The casting method uses an aluminum alloy with a high strength-to-weight ratio that is suited for applications requiring both high strength and low weight.

Cost-effective: Gravity casting is a practical casting technique for aluminum. Small to medium-sized manufacturing runs can be managed with straightforward procedures and low equipment requirements.

Process of Aluminum Gravity Casting

The following steps are included in the aluminum gravity casting process:

The mold’s preparation: The mold is prepared by making a casting pattern. The mold cavity is then made by packing sand tightly around the pattern in a flask.

Aluminum alloy melting: In a furnace, the aluminum alloy is melted. The furnace’s temperature is managed to ensure that the aluminum is melted at the proper temperature.

Melted aluminum being poured into the mold: The molten aluminum goes into the mold cavity using gravity. A casting is created when molten metal occupies the cavity and solidifies.

Cooling and solidification of the casting: The casting is left in the mold to cool and harden. The shape and intricacy of the casting determine the cooling time.

Casting removal from the mold: The casting is taken out of the mold once it has cooled and solidified. The casting is cleaned and completed in accordance with the needed standards.

Applications of Aluminum Gravity Casting

Many industries use aluminum gravity casting because it is accurate, precise, and economical. The following are a few applications for aluminum gravity casting:

Automotive industry: Engine blocks, gearbox boxes, and other automotive components are produced using aluminum gravity casting.

Aerospace industry: The aerospace sector uses aluminum gravity casting to create components for spacecraft and airplanes.

Electrical industry: The production of parts for electrical equipment uses aluminum gravity casting.

Medical industry: Medical equipment components are produced using aluminum gravity casting in the industry.

Defense industry: Components for military equipment are produced in the defense sector using aluminum gravity casting.

Sports equipment industry: Aluminum gravity casting has applications in the sports equipment business to create parts for sporting goods.

Comparison with Other Casting Methods

Compared to other casting techniques like sand casting and die casting, aluminum gravity die casting has a number of benefits. Die casting involves pouring molten metal into a die at high pressure, and sand casting involves making the design of the casting in the sand.

Aluminum gravity casting delivers a higher level of accuracy and an improved surface polish as compared to sand casting. Aluminum gravity casting is more affordable and appropriate for small to medium-sized manufacturing operations as compared to die casting.

Aluminum gravity die-casting material

Aluminum gravity die-casting can be done with a range of aluminum alloys, depending on the application. Gravity casting uses a number of aluminum alloys, including:

A356: The aluminum alloy A356 is extensively used in gravity casting and is renowned for its outstanding strength, good flexibility, and exceptional corrosion resistance.

A357: This aluminum alloy is comparable to aluminum A356 gravity casting but is better suited for high-temperature applications due to its increased silicon content.

A380: The outstanding casting qualities, superior strength, and great corrosion resistance of this aluminum alloy are well known.

A319: Applications requiring high strength, great corrosion resistance, and acceptable machinability demand this particular aluminum alloy.

A413: This aluminum alloy serves in applications where high strength, good weldability, and strong corrosion resistance are required.

A535: This aluminum alloy is commonly used in applications that call for high levels of machinability, exceptional corrosion resistance, and strength.

A712: Applications requiring high strength, outstanding corrosion resistance, and exceptional weldability require this aluminum alloy.

In order to guarantee the best performance and durability, it is important to choose the right aluminum alloy for the particular application.

Finding A Reputable Manufacturer of Aluminum Gravity Die Casting

It’s important to choose a trustworthy aluminum gravity die-casting manufacturer if you want to get castings that are of the highest caliber and satisfy your particular needs. Here are some recommendations for how to find a reliable manufacturer:

Research: Start by searching online for possible producers of aluminum gravity die casting. Look for businesses with a solid reputation, satisfied clients, and relevant experience.

Verify their credentials: In order to confirm that the manufacturer has a quality management system in place, look to see whether they have any certifications, such as ISO 9001.

Request for samples: Request samples of their prior work in order to determine the standard of their castings and guarantee that they can suit your specific needs.

Communication: Make contact with the manufacturer and be specific with your demands. A trustworthy manufacturer should be available, skilled, and capable of offering you technical help and guidance.

Production capability: To make sure the manufacturer can meet your production demands and deliver the castings on time, inquire about their production capacity.

Pricing: Make sure you are paying a reasonable price for the castings’ quality by comparing the prices of several manufacturers.

Visit the location: Visit the manufacturer’s facilities if you can to observe their machinery, manufacturing procedures, and quality assurance procedures.

These steps will help you find an experienced manufacturer of aluminum gravity die castings that can provide castings that are of the highest caliber and satisfy your particular needs.

Do We Need to Buy Chinese Aluminum Gravity Die Castings?

The decision to purchase aluminum gravity die casting from a Chinese die-casting company depends on a number of factors. China is a significant producer of aluminum gravity die casting, so there are numerous die-casting companies there that provide castings of excellent quality at affordable costs.

However, there are certain concerns involved with purchasing aluminum gravity die casting from China, including poor quality, lengthy delivery times, and communication difficulties.

Here are some considerations to keep in mind whenever purchasing aluminum gravity die castings from China:

Quality: Be careful to investigate the manufacturer’s quality assurance procedures and get samples to assess the castings’ caliber.

Communication: Make sure the manufacturer is open to your questions and can communicate clearly in your language.

Price: To make sure you are receiving a reasonable price for the castings’ quality, compare the pricing of other Chinese die-casting companies.

Delivery Period: Verify the delivery schedule of a Chinese die-casting factory to make sure the castings will arrive on time.

Reputation: Verify the reputation of the manufacturer by reviewing it and requesting recommendations from other clients.

Customs and import regulations: If you want to import castings without running into any problems, be informed of the import laws and customs procedures in your nation.

If we do our research and select a reputable aluminum die-casting company that can provide high-quality castings at a fair price, purchasing aluminum gravity die-casting from China may be a suitable alternative.

Conclusion

Aluminum Gravity die-casting is a widely used casting technique because it is accurate, precise, and economical. In comparison to other casting techniques, it has a number of advantages and works best for small to medium-sized manufacturing operations.