CNC machining is an automated process of cutting material by a machine that includes a controller and electric drives that operate according to data provided to it by a technologist or operator.

However, CNC machining is only the last stage of a much wider process. In fact, CNC technology consists of 3 stages:

1. Part model in a computer program

At this stage, a model of the object is made in a specialized computer program. This digital model visualizes all aspects of the workpiece and is the basis for the machine software.

2. Machine control plan

The CAD design must now be translated into a language understood by a computer-controlled machine tool. CAM programs, based on 2D drawings or 3D objects, create instructions on how to move the CNC milling or lathe tool.

3.CNC machining

This is the last stage in which the computer-controlled machine performs cutting according to the loaded CAM program.

What are the different types of CNC machining?

CNC machining allows you to shape surfaces made of any material. However, most often CNC machining is used in the metal industry as machining of aluminum, machining of steel and other metals.

Due to the way in which the CNC machine tool works and the shape we obtain, we distinguish:

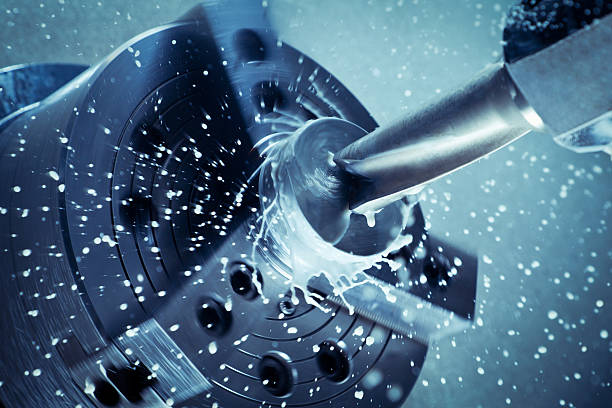

- CNC milling – here the machine blades move over a stationary object and we get grooves, cuts, threads or teeth.

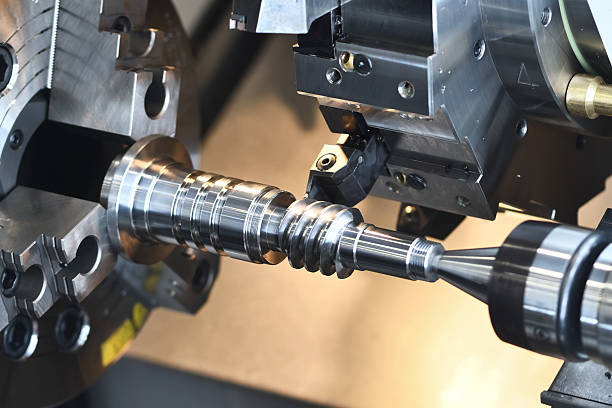

- CNC turning – here, the workpiece rotates and the turning tool moves along its surface. Thanks to turning, you can give cylindrical, conical and spherical shapes to the workpiece.

What are the advantages of CNC machining?

The possibilities of CNC machining for modern industry cannot be overestimated.

Mass production

CNC technology has made it possible to shorten production processes, even in the case of objects with complex shapes. Thanks to this, products can be manufactured in series to meet the ever-growing market demand.

Standardization of production

CNC machining allows you to cut surfaces with extreme precision, thanks to which we obtain semi-finished products with identical properties, which allows for the standardization of production.

Product quality and reliability

CNC machining precision also means higher quality of manufactured items. Thanks to computer control, errors resulting from human inattention or fatigue have been minimized. The precision of workmanship also extends the life of the product.

Production flexibility

CNC machining enables efficient execution of many versions of the item. Just modify the CAM program to get new production parameters.

Economization of production

Thanks to the accuracy with which the CNC machine works, the material can be optimally used, which, combined with shorter production times, reduces production costs.

Work safety

CNC machining does not require direct contact between man and machine. The specialist only supervises its operation via the interface. Thanks to this, the safety of the machine operator’s work increases.

CNC machining – challenges of Industry 4.0

CNC technology – apart from many advantages – poses many challenges to the industry.

The high price of machines

CNC machine tools are electronic devices, so the cost of their production and maintenance is definitely higher than conventional machine tools.

Highly qualified operators

To operate a CNC machine tool, knowledge of metalworking or cutting tools is not enough. The CNC operator must also have programming knowledge. As a result, both the acquisition of the necessary competences and the implementation of an employee in a specific production company take longer.

Cooperation of many production departments

CNC metalworking is a process that requires the coordinated work of many specialists. In order for the cutting effect to meet high standards of approval for use, a system must be introduced:

- quality control,

- measuring,

- maintenance and use of methods to prevent failures,

- designing production processes.

There is no doubt that the metalworking industry will face the increasing challenges posed by the automation of production. We are on the threshold of the 4th industrial revolution, which changes the production process into a large network in which people, cloud IT systems and intelligent devices interact.

What affects the price of CNC machining?

If you are looking for a company that will perform CNC machining for you, you definitely want to know the cost of such a service. Unfortunately, it is impossible to evaluate it without getting acquainted with the specification of a specific order. The cost of CNC machining depends on many factors:

- Type of processed material,

- Thickness of the processed material,

- The degree of complexity of the project,

- Additional services,

- Order size.

That is why in Castingod we give the final price of CNC machining only after we agree with the customer on what his order should look like. We place great emphasis on ensuring that the information about the price is certain for our customers. We also always explain where the valuation comes from and what elements it consists of.

CNC machining – Get a Free Quote Online

At Castingod, we offer both CNC milling services, and CNC turning services, as well as many additional services – washing, aluminum anodizing, laser marking, and assembly.