Cost of Die Casting Service

| Study Period: | 2018-2027 |

| Fastest Growing Market: | Asia-Pacific |

| Largest Market: | Asia-Pacific |

| CAGR: | 5.92 % |

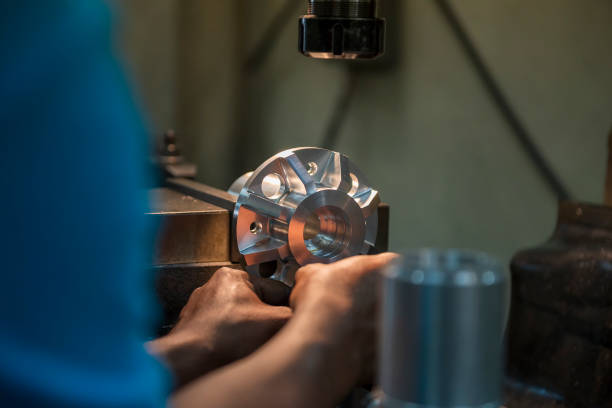

Die casting is a widely used manufacturing method in the aerospace, automotive, and energy sectors. While die-casting is popular, many companies are concerned about the cost, as evidenced by the cost-estimating procedure they use with die-casting services before considering the method.

Discovering how to optimize die casting cost is critical before you can enjoy high dimensional precision, suitability for making complicated parts, recyclable materials, and rapid productivity. As a result, this article will cover die casting cost, the contributing factors, and optimization strategies.

Is Die Casting Costly?

Die casting can be very expensive. As a result, many companies consider the expense as a major drawback that even outweighs the benefits. The process’s high cost is only noticeable when producing a small number of pieces.

Therefore, die-casting services urge companies to use the procedure while producing huge products. The following factors are often responsible for the cost.

Material Cost

Materials are a major factor in die-casting cost since they affect the sort of mold you can create, the die-casting procedure to utilize, and the casted product’s quality. The cost is also influenced by the unit price, part volume, material density, and weight of the material.

The casting quality depends on the material you use, and it also influences the cost of die casting. For example, aluminum is a favorite die casting material due to its quality. Consequently, there is a high aluminum die casting price.

Materials might be expensive if they are relatively rare or need a special technique. For example, the fact that an aluminum casting cost calculator only works with the cold chamber die-casting process results in high aluminum casting costs. Materials like magnesium are similarly affected.

Production

Die-casting costs are a result of a complicated network of elements. Here, labor and the type of machine are the two main factors that most people consider. Large parts, for example, call for a machine with a strong clamping force corresponding to a high die-casting machine price. Additionally, some materials with a high flow will need more expensive, greater tonnage machines.

You can also cut manufacturing costs by reducing cycle time and part wall thickness.

Tooling

Die casting is expensive in part due to the necessary tooling. For example, high-design die-casting tooling will need a production process with a high dimensional tolerance. Additionally, a material that can provide these qualities will be needed for a mold for producing huge parts, which will translate to a high cost.

The high cost of die casting is caused by a number of elements, including the price of the casting tools, materials, molds, and mold-related parts. The one you could improve is the mold and casting procedure.

How to Reduce the Cost of Die Casting Service?

The die-cast mold is the “container” with an arrangement into which the molten metal is injected. The materials and design of the die-casting mold have a significant impact on its price. The impact of the following elements on mold cost and potential cost-saving measures are shown below.

Die Cast Mold Design

Die casting costs will be reduced by a straightforward design. But you can’t just pick something simple if it doesn’t fit your idea or won’t work. You take into account the following when designing die-casting tools:

Labor Cost

The cost of die-casting is also influenced by automation. Labor involvement in the process itself or in its setup is acceptable. By choosing reputable die-casting services and an automated process, you may cut the setup and direct labor costs.

Finishing Options

The casting needs to have a tough, protected surface that also has the required aesthetic appearance. Die-casting costs can vary depending on your finishing options. You have the ability to use common finishing techniques like painting, plating, antiquing, and ceramic coating.

Proper Tooling Maintenance

The die-cast mold needs to be properly maintained regardless of the type of die-casting machine used. A mold used in chamber die casting will experience increased deformation due to its handling of materials with a high melting point. The process of maintaining an existing mold is simpler and quicker. In order to maintain:

- Predicting how long the mold will last

- Creating a potential maintenance protocol.

- Eliminating the mold with compatible cleaning tools and supplies

- Maintaining the die-casting mold in good condition for use later

Aluminum Die Casting Costs

Mold complexity is a significant cost element for projects involving aluminum die casting. CNC machining will be required for some secondary procedures if you need to make complex pieces and the design cannot be accomplished by the mold itself. It is also important to keep in mind there is a limit to how much lower the unit price can go by increasing the quantity in the table below.

| No. | Material | Finish | Quantity | Unit Price | Tooling Cost | Lead time Days |

| 1 | Aluminum | As machined | 500 | £6.91 | £4,992.00 | 32 |

| 2 | Aluminum | As machined | 5000 | £5.18 | £4,992.00 | 32 |

| 3 | Aluminum | As machined | 50000 | £5.18 | £4,992.00 | 32 |

Conclusion

You should be aware of multiple factors that have a major effect on the cost of the process before selecting die casting as the sheet metal manufacturing method for your project. The materials used, the method used, and the equipment used are common aspects that you need to be able to adjust. This article discussed the various elements that affect die-casting costs and how to most effectively use them.