Global Aluminum Die Casting Market Definition

The global aluminum die-casting market is the process of creating metal objects by pushing molten metal into a die or mold under heavy pressure.

It is a flexible die-casting method used to make parts and components with complex forms and shapes. This process is widely used in a range of industries, including the automotive market, aerospace, heavy machinery, and electronics.

This procedure is less expensive than welding and stamping.

High Pressure Die Casting Market Report and Forecast 2023-2028

1. Executive Summary

The high-pressure die-casting process involves injecting molten metal under great pressure into a mold cavity. It is a quick, affordable, and reliable technology used to create intricate and complex-shaped parts with nearly net geometries.

High-pressure die-casting technology is used to create components for a wide range of business and consumer industries, including the automotive, electronics, aerospace, and healthcare sectors.

High pressure die casting market is expected to expand at a CAGR of 4.2% from 2023 to 2028.

Some of the factors driving the market’s growth include growing demand for lighter and stronger automobile parts, greater use of aluminum in the automotive market, and increasing need for high-pressure die casting from the manufacturing of medical instruments.

The research report covers the high-pressure die-casting market’s current state and future market growth prospects for the years 2023 to 2028. The research offers a detailed examination of important market developments, drivers, opportunities, and challenges, as well as the competitive landscape.

The research also goes over the major approaches used by the major players competing in the sector.

2. Market Overview

The market for high-pressure die casting is accelerated by the rise in demand for the manufacture of stronger and lighter automotive parts. High-pressure die casting is used to manufacture a variety of automobile components, including engine parts, cylinder heads, transmission cases, and suspension systems.

This procedure is used to create components with complex geometries and precise details that are challenging to produce using other manufacturing techniques.

Additionally, the market is expected to grow because of the growing use of aluminum in the aerospace and automotive sector.

Aluminum is a lightweight material that has great strength and corrosion resistance, making it ideal for manufacturing automobile components and parts.

High-pressure die casting is an effective way to create aluminum automotive components due to its great dimensional precision and surface finish.

Moreover, the market is expected to grow because of the increasing need for high-pressure die casting in the manufacture of medical instruments.

High-pressure die casting allows for the manufacturing of medical equipment with better accuracy, great precision, strength, and dimensional stability. Such die-casting methods are used to make parts for pharmaceutical products such as blood pressure monitors, syringe plungers, and syringe bodies.

Moreover, the high price of die-casting machines is anticipated to hamper industry expansion. High-pressure die-casting equipment is expensive and requires a huge investment.

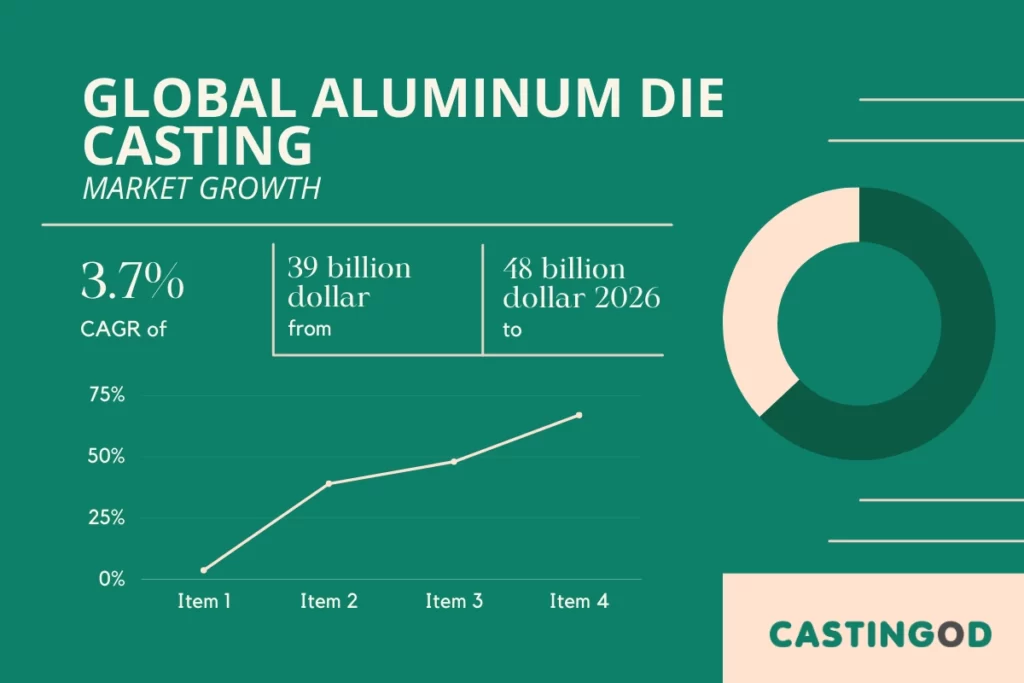

Global Aluminum Die Casting Market Growth Overview

The aluminum die-casting market is driven by rising automotive industry demand as well as the rapid expansion of the consumer electronics and electrical appliance industries.

The market is expected to keep growing as a result of the rising need for lightweight, strong, and affordable components for a variety of applications.

Aluminum die casting has various advantages, including excellent dimensional precision, good surface polish, low labor costs, and a large range of design options.

These advantages make aluminum die casting the chosen raw material for a wide range of applications in industries such as automotive, electronic goods, and electronic equipment.

Aluminum Die Casting Market Drivers

One of the main factors driving the development of the aluminum die-casting market is the rising need from the automotive industry. Automotive parts including cylinder heads, engine blocks, and transmission cases commonly use aluminum die casting.

The demand for aluminum die casting is rising as manufacturers focus on making their vehicles lighter to meet strict emission standards. Moreover, the car industry uses aluminum casting to create a number of parts, including door handles, fuel lines, and cooling systems.

The aluminum die-casting market is expanding quickly due to the consumer electronics and electrical appliance industries.

Aluminum die casting is used to make components for consumer electronics and electrical appliances such as display frames, bezels, and heat sinks.

The aluminum die-casting market is expected to grow because of rising disposable incomes and rising demand for electrical appliances and consumer electronics.

Segmental Analysis

The aluminum die-casting market is divided into three sections: application, end-use industry, and region.

The market is divided into categories based on application, including industrial applications, consumer electronics, electrical appliances, and automotive components.

The automotive components sector is likely to lead the market because of the increasing need for lightweight and durable components in the automobile industry.

The market is divided into segments based on the end-use industry, including automotive, electronic goods, electrical appliances, industrial applications, and some others.

It is expected that the automobile sector will control the market.

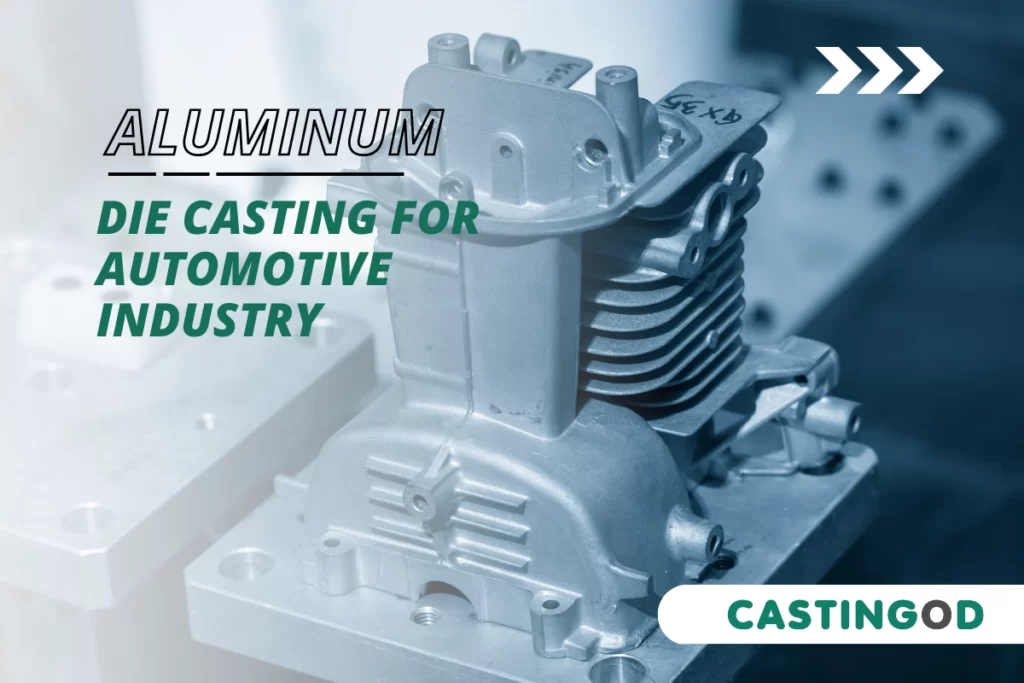

Penetration of Aluminum in the Automotive Industry

In recent years, aluminum has gained popularity in the automotive industry as a strong and lightweight replacement for standard steel and iron materials.

This is due to aluminum’s better corrosion resistance and strength-to-weight ratio, which allows manufacturers to reduce vehicle weight and improve fuel economy. Moreover, aluminum is more environmentally friendly and far more recyclable than traditional key raw materials.

Currently, aluminum is used in a wide range of automobile parts, including engine blocks, exhaust systems, and body panels. It also serves as a lightweight and durable structure for the batteries and motors used in electric cars.

Moreover, aluminum die-casting parts are used in the development of lane-keeping and automatic braking systems.

In general, aluminum usage in the automotive sector is expanding quickly and is expected to do so in the future. What are the main market developments for the global high-pressure die-casting market?

Rising Demand for Aluminum High-Pressure aluminum Die-Casting market

The global aluminum high-pressure die-casting market is predicted to develop steadily because of the rising demand for lightweight components and corrosion-resistant parts in the automotive and other sectors.

The demand for lighter, more efficient and more efficient components is a consequence of increasing vehicle manufacturing. High-pressure die-casting components made of aluminum are also in high demand due to the growing demand for energy-efficient components.

The market is also expected to grow as a result of the increasing use of aluminum for electric vehicles and its rising demand in the transportation sector. In addition, the market for aluminum high-pressure die-casting components is expected to be driven in the near future by the increasing need for 3D printing technologies.

According to the EMR Market report, what are the key regional markets of high-pressure die casting?

The primary regional markets for high-pressure die casting, according to the EMR research, are North America, South America, Europe, Asia Pacific region, Latin America, the Middle East, and Africa.

North America is likely to lead the worldwide market because of the growing demand for low-weight, high-strength, and cost-effective components manufactured using high-pressure die casting.

Asia Pacific is expected to grow greatly because of the rising need for low-cost components in the automotive and electronic goods industries.

Europe is also likely to be a prominent market for high-pressure die casting because of growing demands from the automotive and aerospace industries.

Which Are the Industry Major Players in the Global High-Pressure Die Casting Market?

The major companies competing in the international high-pressure die-casting market are

Metaldyne Performance Group Inc. (U.S.),

Dynacast International Inc. (U.S.),

Grainger & Worrall Ltd. (U.K.),

Rheinmetall AG (Germany), and Dynacast International Ltd. (U.S.)

What are the significant applications of high-pressure aluminum die-casting?

1. Automotive Parts: High-pressure die casting is commonly used to make intricate auto parts like engine blocks, gearbox housings, suspension components, and wheels.

2. Industrial Parts: The manufacture of complicated, complex parts for industrial applications, such as pumps, valves, and other machine parts, uses high-pressure die casting.

3. Consumer Goods: High-pressure die casting is widely used to make products like door knobs, locks, kitchenware, toys, and sporting goods.

4. Aerospace Components: High-pressure die casting is used to produce metal components for engines and structural components of airplanes and spacecraft.

5. Electronics: Heat sinks, connections, and enclosures are some of the components made for electronic devices using high-pressure die casting.

Which Region Has the Largest Share in High-Pressure Die Casting Global Market?

North America currently holds the greatest market share in the high-pressure die-casting global market, with 38% of the total market share.

Asia-Pacific region comes in second with over 33% of the global market share, followed by Europe with roughly 22% of the global market share.