The manufacturing procedures of injection moulding and injection moulding are widely utilised to mass-produce high-quality components. Both methods have advantages and disadvantages and can be used for various tasks. In this piece, we’ll examine the pros and cons of two common manufacturing processes: injection moulding and injection moulding.

A definition of injection moulding would be helpful.

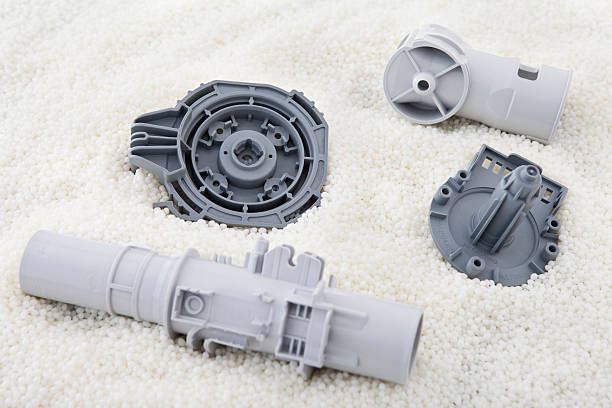

Parts can be mass-produced using the manufacturing technique of injection moulding. Mould cavities are filled with molten plastic, which then cools and hardens into the final product.

Benefits of Injection Molding

The advantages of injection molding include:

• High performance

• Low labor cost

• Ability to create complex shapes

• Consistent part quality

• Low scrap rate

Disadvantages of Injection Molding

The disadvantages of injection molding include:

• High initial tool cost

• Limited choice of materials

• Long tooling time

• Restrictions on the size and thickness of the part

What is die casting?

Die casting is a manufacturing process used for the mass production of metal parts. It involves injecting molten metal into a mold cavity under high pressure. The metal solidifies and cools, taking the desired shape.

Benefits of Die casting

The advantages of injection molding include:

• High performance

• Ability to create complex shapes

• Good surface quality

• High strength and durability

• tight tolerances

Disadvantages of Die Casting

The disadvantages of injection molding include:

• High initial tool cost

• Limited choice of materials

• High percentage of marriage

• Restrictions on the size and thickness of the part

• End part porosity

Comparison of injection molding and Die Casting

Injection molding and die casting have some similarities and differences. Here is a comparison of the two processes:

• Materials: injection molding is used to make plastic parts, and die casting is used to make metal parts.

• Process: In injection molding, molten plastic is injected into the mold cavity, and in die casting, molten metal is injected into the mold cavity.

• Productivity: Both processes have high productivity, but injection molding is faster than die casting.

• Cost: Both processes require higher initial tooling costs, but die casting is cheaper than injection molding.

• Material Options: Injection molding has more material options than injection molding.

• Part size and thickness: injection molding is suitable for making small and medium sized parts, and die casting is suitable for making medium and large sized parts.

• Scrap rate: injection molding has a lower scrap rate than injection molding.

When to Use die casting?

Injection molding is suitable for making:

• Small and medium sized plastic parts

• Precision parts with tight tolerances

• Complex shape

• Thin-walled parts

• Parts with inserts

When using injection molding?

Injection molding is suitable for making:

• Medium to large metal parts

• High strength and durable parts

• Thin-walled complex shape

• Parts with tight tolerances

• Parts with good surface finish

Steps of the injection molding process

The injection molding process usually includes the following steps:

• Material preparation: Melt the plastic resin and prepare it for injection.

• Injection: Molten plastic is injected into the mold cavity under high pressure.

• Cooling: The plastic cools and solidifies inside the mold cavity.

• Eject: The part is pushed out of the mold cavity.

• Post-processing: Parts may require additional processing or assembly.

Die Casting process

The injection molding process usually includes the following steps:

Die casting is a metal casting process in which molten metal is injected into a mold cavity under high pressure. This process is widely used in various industries such as automotive, aerospace, and electronics because it produces complex geometries with tight tolerances and excellent surface finish. This section uses SEO keywords to explain the injection molding process in detail.

Diagram of Die Casting process

The injection molding process includes the following steps:

4. Cooling

When molten metal is injected into the mold cavity, it begins to cool and solidify. The cooling time depends on the materials used and the size and complexity of the part being made.

5. Ejection

After the metal has cooled and solidified, the part is pushed out of the mold cavity. Ejector systems typically consist of an ejector pin that ejects the part from the mold cavity.

6. Cropping

After the part is removed from the mold cavity, excess metal is removed from the part. This excess metal is called burr and is removed with a trim die.

7. Post-processing

Finally, parts may require additional finishing and assembly. This includes sandblasting, polishing or painting a part, or assembling it with other parts to create a finished product.

Injection Molding and die casting Statistics

• Injection molding is used to produce over 30% of all plastic products in the world.

• The global injection molding market is expected to reach $537.8 billion by 2025, growing by an average of 5.7%.

• The global injection molding market is expected to reach US$89.5 billion by 2025, growing by an average of 6.1%.

Conclusion

Injection molding and die casting are two common manufacturing processes used to produce high-quality parts in high volume. Both processes have their strengths and weaknesses and are suitable for different types of applications. Factors to consider when deciding which process to use include materials, production speed, costs, material options, part size and thickness, and scrap rates.

Recommendations

• Injection Molding Market Valued at $537.8 Billion by 2025: Grand View Research, Inc., PR Newswire, 2017.

• “Injection Molding Market Worth $89.5 Billion by 2025: Grand View Research, Inc.”, PR Newswire, 2017.