There are various materials used in casting. These include aluminium, zinc, copper, steel, etc. These materials have distinct features.

In modern casting, aluminium and steel are two top choices for casting manufacturers. You may be wondering which one is stronger between both. Right?

That’s exactly what we will show you here. Steel is stronger than aluminium , but aluminium’s extensibility is better.

What is cast aluminium?

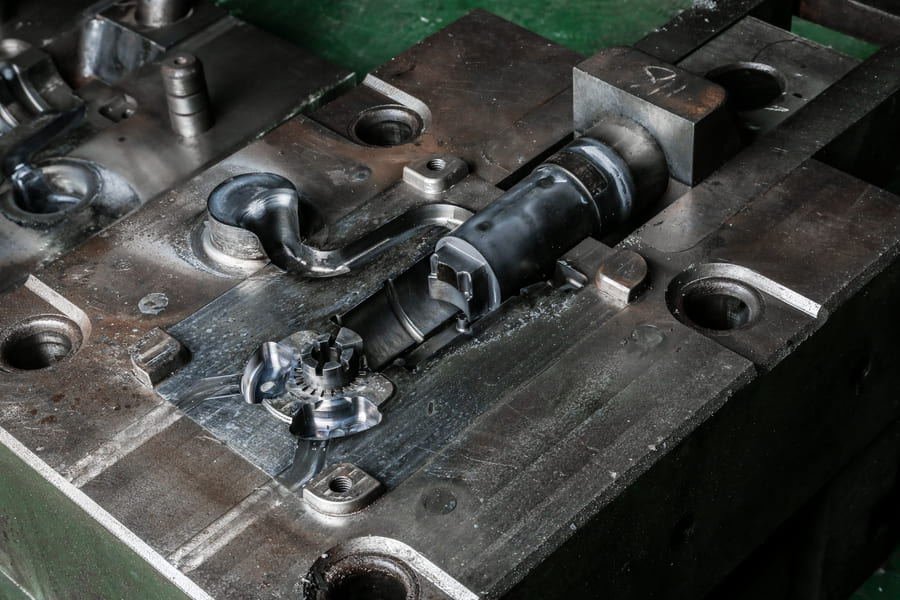

Cast aluminium is the aluminium melted in a furnace and poured into a mold. After solidification, the casting will be removed from the mold.

The various stages in aluminium casting include mold preparation, making the gating system, lubricating the internal surface, injection of the molten metal, solidification, removal of the casting, machining, trimming, and finishing.

The methods of casting aluminium include pressure die casting, gravity die casting, investment casting, sand casting, centrifugal casting, vacuum die casting, lost foam casting, etc.

Although each of these methods is different from one another, they mainly involve pouring molten metal into the mold and allowing it to solidify.

What is aluminium?

The material used in cast aluminium is aluminium. Aluminium is a silver-white metallic chemical element that has good electrical and thermal conductivity. It has high reflectivity and is reactive to oxidation. So, it is corrosion-resistant. It is also lightweight.

It has a solid, non-magnetic, non-lustrous appearance. It also has high ductility and a face-centered cubic structure that is stable up to the melting point. It has high malleability as it can be easily bent or shaped.

Aluminium is the most widespread metal on earth. It constitutes over 8% of the earth’s core mass. It is also the third most common element on the earth.

It occurs as a compound, and mainly found in bauxite ore. The commonest form of aluminium is aluminium sulphate. Before you can realize pure aluminium, it would go through a production process.

Other elements are also added before realizing pure aluminium. These elements include copper, aluminium, manganese, zinc, silicone, etc.

This explains why there are different aluminium alloys with their peculiar features. These alloys include A403, 3003, 6061, 6082, 6063, and 5251.

What is cast steel?

To make cast steel, you will melt the steel in a furnace and pour it into a mold. After solidification, you will separate the casting from the mold.

It has a similar production process to aluminium casting. The production process involves mold preparation, making of the gating system, injection of the molten steel, solidification, removal of the casting, machining, trimming, and finishing.

Note that it may be quite difficult to pour steel into the mold. This is because steel is less fluid and more reactive to mold materials.

Also, steel shrinks more when it cools; so you need to pour more liquid steel into the mold.

Cast steel have lower mechanical properties than wrought steel. However, they have the same chemical compositions. Cast steel contain 0.1-0.5 carbon. This carbon composition makes the casting to be very hard.

What is steel?

Cast steels are made from steel. So, it is necessary to note what steel is. Steel is one of the world’s most important casting materials.

It is an alloy containing iron and a few tenths of a percent of carbon. The carbon composition improves the strength and fracture resistance of the steel.

Typically, steel comprises 98 iron, less than 2% carbon, 1% manganese, and little amounts of phosphorus, silicon, sulphur, and oxygen. However, in making steel, other elements may be added.

These other elements include molybdenum, nickel, manganese, titanium, cobalt, or vanadium. Also, stainless steel that are corrosion-and-oxidant-resistant require 11% chromium.

The interaction of the allotropes of iron with the alloying elements and carbon gives steel their unique properties.

Particularly, steel are very hard because of their composition. Steel alloys usually contain below 2% carbon. The carbon meets with iron to create a strong molecular structure.

This leads to lattice microstructure which helps to achieve certain material properties. These properties include hardness, tensile strength, etc.

Steel can withstand friction and abrasions. They are tough and can absorb energy without fracturing or rupturing.

The melting point of steel ranges from 2500-2800°F. However, the exact melting point depends on the steel alloys. Broadly, there are four types of steel. These are carbon steel, tool steel, alloy steel, and stainless steel.

Cast aluminium and steel: Which is stronger?

Generally, steel is stronger than aluminium. Aluminum dent, scratch, and ding more easily than steel. You know why? It is because of the composition of iron, carbon, and other elements in steel.

Pure iron only has identical atoms of iron. The structure of atoms in pure iron is flexible. These atoms can glide away; this is known as dislocation. If a load is applied, it results in dislocation which causes the material to fall. So, cast parts solely made with iron are not strong. They (relatively) give away easily under high pressure.

On the other hand, the elements in steel have varying atomic sizes. So, when you apply a load, the atoms cannot slip through easily due to their disorderly arrangement. This makes steel more rigid and stronger.

The higher the carbon composition in steel, the stronger the steel. For example, steel with a 2.0% carbon composition will be stronger than steel with 0.002% carbon.

Note that heat treatment also influence steel strength. Carbon strengthens iron by distorting its crystal lattice. When steel is heat treated, it quenches rapidly from a very high temperature.

Excess carbon atoms will be trapped in the iron crystal lattice, and this distorts the lattice. This distortion hardens the steel. In heat treatment, steel with lower carbon content requires more temperature to make it stronger.

Are some aluminium alloys stronger than some steel?

We have emphasized that steel is generally stronger than aluminium. However, note that some aluminium are stronger than some steel.

For example, aluminium alloys Grade 7000 and 7075 are extraordinarily high-strength alloys. They are among the strongest of all commercial grades of aluminium. Particularly, Grade 7075 is stronger than many types of mold steel.

Contrast between cast aluminium and steel

• Steel does not melt until it reaches a temperature around 2500°F. Conversely, aluminium melts at 900 degrees F. So, steel cast parts have a higher melting temperature than aluminium.

• Aluminium cast parts have excellent electrical and thermal conductivity. On the other hand, steel parts have dense protective oxide layer; so they are poor conductors of electricity

.

• Aluminium cast parts are more lightweight than steel’s. They have around 1/3 weight of steel.

• Aluminum cast parts are corrosion-resistant. They can withstand outdoor exposure. Steel is rather susceptible to corrosion.

• It is easier to machine aluminium cast parts than steel’s.

• Aluminium is more malleable and elastic than steel. You can cast aluminium into intricate and deeper shapes. Conversely, you can not push steel into the same extreme dimensional limits as aluminium.

Conclusion

Generally, steel is stronger than aluminium. However, among others, aluminium is lightweight, malleable and elastic, and have excellent electrical and thermal conductivity than steel. It is also corrosion-resistant.

So, in choosing between aluminium and steel for your casting, you should holistically consider the distinct features of both materials. And then decide which one suits your purpose.