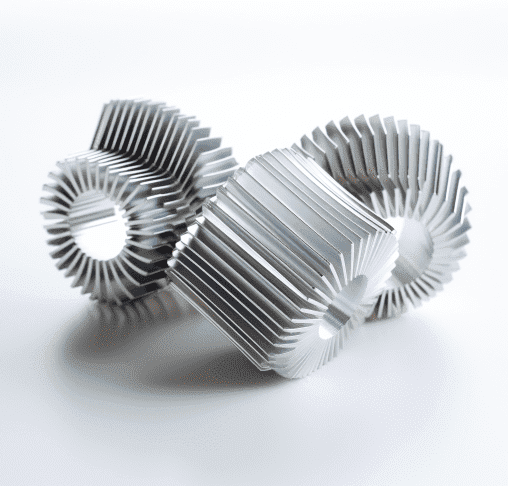

Aluminum die casting for LED heat sinks

An LED heat sink dissipates any heat through multiple fins when the led lighting is on. Aluminum die casting is the most common production method for making custom part. There are different reasons LED heat sinks are an excellent choice for lighting applications. For instance, aluminum is lightweight and has good thermal conductivity and thermal conductivity.

No matter your design, our experts are happy to craft customized heat sinks guaranteed to prolong the life of your LEDs.

- Street Light

- Floodlights

- Bulb lamp

- Fire Fighting Light

- Spotlights

Aluminum Die Casting for LED Heat Sinks: Key Benefits

- • Excellent Heat Transfer: In order to ensure optimal LED performance, aluminum effectively absorbs heat.

- • Versatile and lightweight: In lightweight designs, aluminum offers versatility and robustness.

- • Resistance to Corrosion: The natural oxide layer on aluminum provides strength and corrosion protection.

- • Cost-Effective: Cost-effective manufacture for large volumes is offered by aluminum die casting.

In conclusion, aluminum die-casting guarantees effective heat transmission, lightweight adaptability, financial viability, and corrosion resistance for premium LED heat sinks.

Comparing Materials for LED Heat Sinks

Comparison Between Die Casting and Extrusion for LED Heat Sinks

Complexity

- Die casting: Molds are used in a complicated process that requires careful injection and cooling control of aluminum alloy.

- Extrusion: No need for complicated molds, making the procedure simpler.

Cost-effectiveness

- Die casting: More expensive due to the creation and upkeep of the mold. Mass production-friendly to reduce unit costs.

- Extrusion: Cost savings because molds are not needed. restricted to more basic sizes and shapes.

Thermal effectiveness

- Die casting: Greater surface area for heat dissipation and improved thermal performance thanks to intricate interior structures and heat sink designs.

- Extrusion: Due to reduced surface area and simpler heat sink designs, thermal performance is somewhat poorer.

Production time:

- Die casting: Debugging and mold manufacturing take more time during production.

- Extrusion: Less time is spent on production because molds are not needed, which enables quick changes to extrusion parameters.

In conclusion, die casting is more ideal for mass manufacturing and has superior thermal performance, but it also has greater costs and a longer production time.

Extrusion is more economical and quicker to produce, but it has restricted design options and delivers rather poor thermal performance. For the construction of your LED heat sink, your individual needs and budget will determine whether to use die casting or extrusion.

Surface Treatment Options for Improving LED Heat Sink Performance

Different surface treatments can be applied to LED heat sinks to improve their look, durability against corrosion, and heat dissipation capabilities. The following are some popular surface treatment procedures for LED heat sinks:

Anodizing: In order to boost the aluminum heat sink’s durability, ability to resist corrosion and aesthetic appeal, a coating of oxide is typically formed on its surface. Additionally, anodizing provides alternatives for various colors including black, silver, and gold.

Painting: Painting is putting a coat of paint on the surface of the heat sink to give additional protection and ornamental benefits. Depending on the needs, different shades and paint kinds, such as liquid paint or powder coating, can be selected.

Electrophoretic Coating: In electrophoretic coating, charged particles are suspended in a liquid paint and applied to the surface of the heat sink by an electric field. This process offers a uniform coating, strengthens durability, and reduces corrosion.

Sandblasting: Sandblasting is the process of high-speed blasting sand particles onto a heat sink surface to improve its texture and roughness, which enhances appearance and improves heat dissipation performance.

Polishing: To produce a flawless, mirror-like quality, the heat sink surface is manually or chemically polished. The aesthetics and corrosion resistance of the heat sink are improved by polishing.

Above surface treatment techniques can be chosen based on particular requirements and cost limitations. To satisfy client needs, choosing the right surface treatment technique can improve the quality, effectiveness, and aesthetic appeal of LED heat sinks.

Customer Success Stories

Customer: THOSHIBA

Customer: YAMing

Customer: OUPER

Customer: ROLODS

Let Castingod.com boost your business today!

Castingod have been in the business of aluminum die casting in China for more than 20 years, let a true industry veteran provide you with high quality casting parts