What is die casting process?

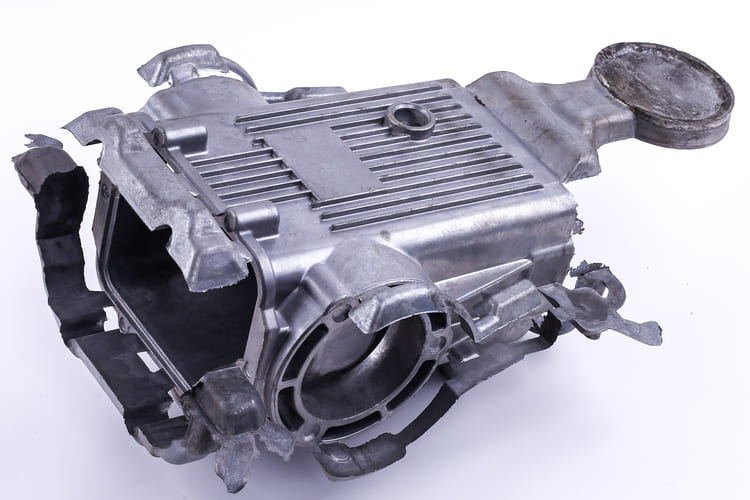

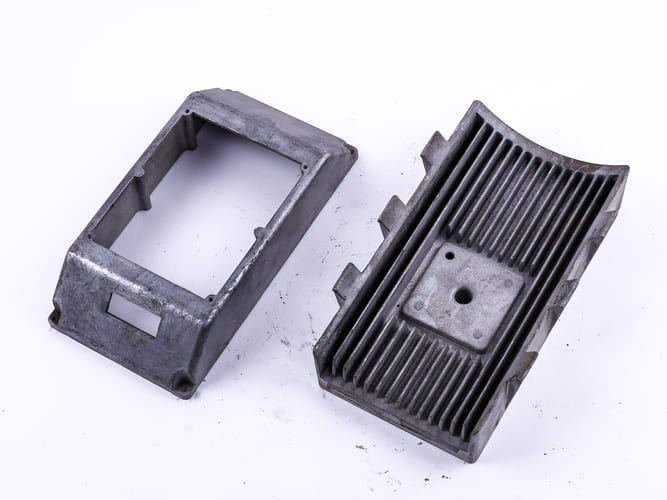

In the die casting process, which is used to create metal products, molten metal is injected under intense pressure into a meta mold that can either be used repeatedly or just once. The process of high pressure die casting involves feeding molten metal into a die, where it is solidified to produce the desired component. High pressure (typically hydraulic pressure) is used to force the hot metal into the die cavity, where a strong press secures it.

Steel, aluminum, and other metals can be cast using the die-casting technique. There are many suppliers of aluminum die-cast around the world.

How do you know which one is right for you? This can be difficult to decide, especially if you are not familiar with the industry.

We’ll go over a few things you should think about when choosing an aluminum die casting supplier in this blog post. By taking into account these elements, you can select the ideal supplier and save money

1. The current state of aluminum die-casting suppliers in China

China’s manufacturing sector is now at an advanced stage with thousands of large and small aluminum alloy die-casting companies: with most manufacturers situated in Guangdong Province, Zhejiang Province, and Jiangsu Province.

The quality of Chinese manufacturers and suppliers of aluminum die-casting has significantly increased in recent years as a result of the continuous advancement of technology and the upgrading of the manufacturing process.

they are now one of the primary sources of aluminum die-casting products globally. By reducing the amount of defects, cost-effective manufacturing has also assisted in improving the durability of aluminum die casting.

I previously worked in an aluminum die casting parts company and in my interactions with customers, I sensed their confusion and bewilderment in locating suppliers of die cast parts.

The customer’s primary concern when choosing a supplier is the cost of the good, but cost by itself is insufficient; additionally, the die cast must be of acceptable quality and quantity and be delivered on schedule.

Distinctions in Chinese die casting factory settings

Aluminum die casting factories in China each have their own unique traits. For instance, some are modest in size but concentrate on producing high-end die cast ( with demanding precision requirements), while others have a more extensive industrial chain, including mold creation, die casting, machining, surface treatment, assembly, etc.

Therefore, if you are looking for an aluminum die casting manufacturer or supplier, don’t just look at price, but also consider other factors such as quality and delivery time of die casting parts.

Here are some other factors you should consider when choosing an aluminum die-casting manufacturer or supplier

-The size of the die casting supplier

-Condition of the die casting parts

-Capacity of the die casting equipment

2. Determine your requirements -Product requirements and quantity of orders

1. an assessment of the future demand for the die casting equipment, based on a forecast of the market

2. what is the relevance of high quality parts? Whether it is a high demand for precision or a high demand for appearance?

How do you locate the ideal supplier if your demand is modest? How do you locate a supplier who can meet your high demand while providing quality and quantity die casting deliveries on time?

Finding a supplier who can meet your requirements will be simpler once you are aware of what they are.

3. Do your research – find a supplier who specializes in the type of aluminum die casting you need

There are many aluminum die casting factories in China and the die casting industry is now a jungle of superior strength.

You can find several businesses by searching for terms like “aluminum die casting,” “die casting manufacturer,” “aluminum die cast parts,” “zinc alloys die casting products,” etc. Request a quote from the company and include the requirements of your die casting process.

Typically, you can expect a response in one to two days; if it takes longer than that, you can simply exclude this die casting supplier.

4. Obtain quotations from multiple die casting suppliers – compare prices and services offered

How do you choose the best factory for you if, after getting quotes and comparing prices, you discover that their prices are drastically different?

The typical consumer may avoid the factory that offers the highest and lowest quotes and opt for the one with the middle quote. Although this is a widely held belief, you must consider additional factors for convenience

– If your demand is small and your product requirements are not high.

It is best to select a small business, ideally one with fewer than 30 employees, as their low management costs will translate into lower quoted prices.

– If your demand is very small and your product requirements are high.

then selecting a small business is also advised, but the equipment of this business must be compatible with your product, and of highest quality. Such a business will have management expenses at very low cost, so the price it quotes won’t be excessive.

– If your demand is high and your product requirements are not high.

it is also advisable to choose a small company, which can save costs. But this company has enough equipment that

– If your demand is high and your product requirements are also high.

Choosing a big company is recommended. Quality and quantity of production can be guaranteed by a large company with cost-effective tools, but the management costs of a large company are higher and the unit price of the product is relatively much higher.

Of course, if your budget is sufficiently large but there is little demand for the products, you can also select a large company, pay them a high price, and they will still produce.

5. Find out from the supplier who quoted you the size of their company and their equipment

After receiving a quote from a company, you can inquire about their size and whether they have specialized machinery to produce your product.

It is best to avoid selecting companies without the necessary tools. Choose one based on your requirements and the company that the customer provides, not just on price.

6. Communication and service

Building trust between the partners and increasing understanding are both necessary for producing a more suitable supplier during the cooperation process. Efficiency promotes smooth business interactions. If a supplier can work well with you, I believe the price difference is irrelevant because he is still offering a high-quality service.