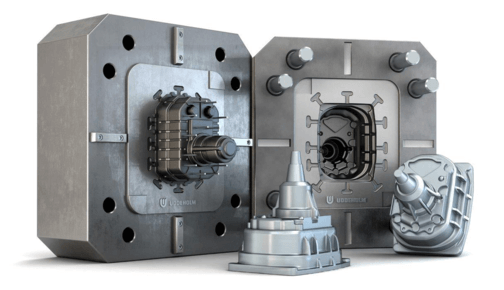

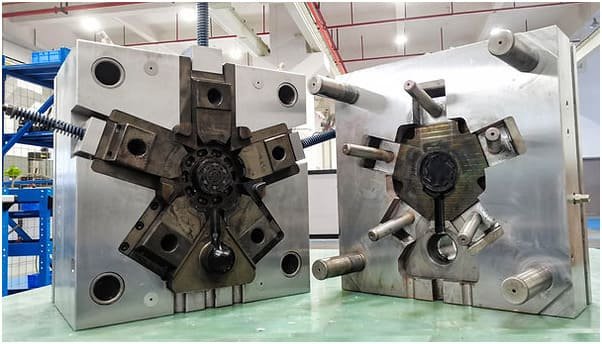

Die-casting is a method of manufacturing metal products, where molten metal is fed into a mold under high pressure. The fast-flowing molten material spreads to all parts of the mold, resulting in the desired shape of the piece. Die casting is well suited for large volumes. The die-casting parts are very dimensionally accurate and mechanically strong.

Castingod

The company specializes in the production of the following parts:

- Architectural parts

- Electrical enclosures

- LED Heat Sink

- Medical Equipment

- Automotive Parts

, following the customer from the initial project to the finished product, with attention to every phase. The vision of the company is to establish itself in the market for the production of die-cast aluminum components constantly increasing the quality and technological level of its products.

Address: Sanbei Industrial Development Zone, Longshan Town, Cixi Zhejiang China

Website: https://castingod.com/

Email for Inquiries: info@castingod.com

Ouneva Group

Ouneva Group is an international industrial contract manufacturer and product development, partner. Long-term development, quick decision-making, and efficient production are our starting points. With a strong attitude, we achieve top quality and exceed our customers’ expectations.

Our wide selection of technologies covers metal, plastic, electronics, and surface treatment manufacturing processes in contract manufacturing. Our highly honed expertise extends from microscopic measuring instruments for medical devices to speakers used in studios or the cabs of mining machines.

Contact: Executive Assistant: +358 50 355 6003

Website: https://www.ounevagroup.fi/

Schmale & Schulte

Welcome to Schmale & Schulte. For more than 50 years, Schmale & Schulte has been developing and producing sophisticated products made of die-cast aluminum, die-cast zinc, and die-cast aluminum.

We support our customers worldwide as a system supplier. Competences from a single source: technology consulting, prototyping, tool making, series production, product refinement, assembly, and logistics.

Address: At the Bellmerei 1, 58513 Lüdenscheid

Website: https://www.schmaleundschulte.de/

MCT FOUNDRY

– High-pressure die casting consists of the injection, under high pressure, of the molten alloy into a metal mold which solidifies quickly to form a workpiece. – This transformation process allows to the reproduction of complex pieces with thin walls. – It is an economical and fast fabrication process for the production in the large production of light alloy parts. – One of these main advantages is to have a high repeatability and a high tool life.

The characteristics of the aluminum used in high-pressure die casting – At equal volume, aluminum has 34% of the weight of steel – Aluminum is an excellent conductor of temperature, 1.8 times better than copper –

Address: Valge 13, 11415, Finland

Website: https://eurobalt.net/it/

Metalcast

The excellence of Metalcast Group in the aluminum die-casting sector is the result of the synergy between the expert practice of the people, the quality of the raw materials and equipment, and the efficiency of the large fleet of machines. Thanks to our network of partners, we can count on a large fleet of machines to satisfy every request: from the smallest 150-ton presses to the largest 2000-ton presses to obtain castings weighing from 50 g up to 16 kg.

Address: Viale Cristoforo

Website: https://www.metalcast.fi

Italpres

italpres operates in the sector of design, construction of molds, and die-casting of aluminum and zinc-aluminum alloys, creating articles for a vast range of sectors, including electronic components, lighting, automotive, telecommunications, textiles, hydraulics, medical, hydraulics, and many others.

A flexible mentality and the contribution of competent personnel have made it possible to welcome the technological innovations of the sector over time and to expand the customer base, first to all of Europe, today but also to the rest of the world.

Address: Via G. Mameli, 10 – Lumezzane

Website: https://www.italpres.fi

Kuka

Foundry products form the basis of an infinite variety of everyday objects, from smartphones to vehicle transmission unit housings. This kind of component is mostly produced by die-casting. KUKA offers integrated and harmonized automation concepts for mold unloading for the production of metal and aluminum components.

In die casting, the molten metal is injected under high pressure into a mold where it solidifies. This process achieves, despite the high speed, a high casting quality, thanks also to the metal cooling process, and is particularly suitable in the case of thin sheets.

The peculiarity of this casting technology is the process in permanent form, i.e. the mould, once created, can be used for tens of thousands of pieces, both in aluminum and in light alloys. For this reason, die casting is particularly suitable in the mass production of structural parts.

Address: KUKA AG, Zugspitzstrasse 140, 86165 Germany and Finland

Website: https://www.kuka.com/it

Fassi

The Fassi foundry has been operating in the die-casting sector for fifty years. The Bergamo-based company produces cold chamber and hot chamber die castings and performs processes such as tumbling, sandblasting, galvanic treatments, and mechanical reworking. The foundry processes zinc, aluminum, zinc alloys, and zamak.

It also deals with the design and construction of molds. Among other products, it also produces aluminum components, components, and accessories for lamps and chandeliers, metal containers and boxes for electronics, motor components, lighting components, and die-cast aluminum boxes. The Fassi foundry offers fast deliveries even for small runs. The company’s sectors of intervention are motoring, industrial and design lighting, the textile industry,

Address: Via Verga, 17 Finland

Modelleria Ferrieri

Modelleria Ferrieri carries out modeling and non-ferrous metal foundry activities. Founded in 1970 by its president Claudio Ferreri, Modelleria Ferrieri began its activity in an artisanal form, limiting itself to the construction of models for foundries. In the current factory, active since the early 1980s and extending over an area of 2500 m2, the modeling shop has been joined by the metal foundry, with a particular focus on bronze castings and special aluminum alloys.

The basic idea was to ennoble the traditional process with the most modern technologies, making Modelleria Ferrieri the safest reference for satisfying current market demands and anticipating future ones. Our goal is to realize every project, even the most innovative and complex,

Address: Via Umbria, 17, Finland

Website: https://www.modelleriafonderiaferrieri.com/

CDM

CDM deals with the production of mosquito nets, aluminum components, aluminum and PVC roller shutters, aluminum windows, roller shutters, and aluminum window frames. The company offers a window replacement and installation service.

It offers after-sales service and fast delivery times. The competent and qualified staff is able to satisfy the various needs of its customers and is available for information and estimates. CDM is based in Rocco d’Evandro, in the province of Caserta, in via Demanio Vandra Ovest 2 bis.

Address: Via Demanio Vandra West, 2

Website: https://www.cdmaccessori.it/