Importance of material selection in die casting

Die casting is a very accurate and successful method of manufacturing metal parts for businesses, consumers, and other industries. Die casting is appropriate for producing intricate metal parts since the tooling is long-lasting and it provides excellent value for large-scale manufacturing.

Many metals can be used to create acceptable die-casting materials. The majority of them are non-ferrous metals, though sometimes ferrous metals may also be used. Non-ferrous metals are those that do not contain a large quantity of iron. Aluminum, magnesium, and zinc alloys are the three main materials used in die casting, and each has unique benefits and useful uses.

This article covers the top die-casting materials and the importance of choosing the right ones.

Die Casting Material Considerations

When selecting materials for die casting, manufacturers must take into account a number of factors and aspects. These consist of:

- The suitability of the material for hot-chamber die casting

- Material costs

- Indirect material costs (such as any additional post-processing needed)

- Material and structural attributes

- Machinability

- Surface finish

- Strength

All of these factors should be focused on when selecting a die-casting material for components or prototypes.

Aluminum die casting alloys

Overview of Aluminum Alloy for Die Casting

Aluminum is one of the most commonly used die-casting metals, and aluminum alloys are used in cold-chamber die-casting. Typically, these alloys include silicon, copper, and magnesium.

Advantages and Disadvantages of Aluminum Alloy

Aluminum die-casting alloys are lightweight and have good dimensional stability, making them an excellent choice for complex, fine-featured products. Good thermal and electrical conductivity, temperature resistance, and corrosion resistance are further benefits.

However, the capacity of aluminum alloys to endure higher temperatures is low, and some high-strength aluminum alloys have poor corrosion resistance, which limits their use.

Common Applications of Aluminum Alloy in Die Casting

Aluminum alloys commonly used in die casting include:

- 380: A versatile aluminum alloy that maintains an equilibrium between cast-ability and strong mechanical characteristics. It can be found in a wide range of products, including engine brackets, furnishings, electronics enclosures, frames, handles, gearbox boxes, and power tools.

- 390: An alloy that has exceptional wear and vibration resistance. It was created especially for the die casting of automotive engine blocks, but it can also be used for pump housings, valve bodies, and impellers.

- 413: A superior casting-quality aluminum alloy. It is used for items like hydraulic cylinders, as well as architectural components and machinery for the food and dairy industries because it has good pressure tightness.

- 443: It is the most flexible of die-casting aluminum alloys. This alloy is ideal for consumer items, particularly those requiring plastic deformation after casting.

- 518: A corrosion-resistant, ductile aluminum alloy. It is used in many different goods, including escalator parts, ornamental hardware, and hardware fittings for aircraft.

Zinc Die Casting Alloys

Overview of Zinc Alloy for Die Casting

Zinc alloys are an important subcategory of die-casting metal. Zinc is a die-casting material that can be cast in a hot-chamber die-casting process while still being manufacturer-friendly.

Advantages and Disadvantages of Zinc Alloy

Zinc alloys are less expensive since they don’t include chromium. They are less suitable for producing things that come into contact with standing water because of their increased corrosiveness. Most producers find it easier to work with zinc alloys.

Common Applications of Zinc Alloy in Die-Casting

Zinc die-casting alloys that are commonly used include:

- Zamak 3: A versatile zinc alloy with outstanding dimensional stability and ease of casting. Zamak 3 is used in more than two-thirds of zinc die castings in North America. Plumbing parts and ceiling fans are a couple of examples.

- Zamak 2: An alloy with greater copper content that is significantly stronger and more expensive. It is commonly used to create the molds needed for plastic injection molding.

- Zamak 5: A zinc alloy that is similar to Zamak 3 in composition but has higher tensile strength and less ductility. It is used for goods like wheel balancing weights and automobile equipment.

Magnesium Die-Casting Alloys

Overview of Magnesium Alloy for Die Casting

Magnesium is another prominent die-casting material. It has the benefit of being even lighter than aluminum and is also very machinable, making it ideal for cast products that need further machined features or a machined surface finish.

Advantages and Disadvantages of Magnesium Alloy

Magnesium die-casting alloys provide a number of advantages over die-casting metals like aluminum, including their suitability for hot-chamber die-casting. Aluminum, zinc, manganese, and silicon are additional components that can be found in magnesium alloys.

Common Applications of Magnesium Alloy in Die Casting

The following are common magnesium die-casting alloys:

- AZ91D: A universal alloy with good castability, anti-corrosion properties, and strength-to-weight ratio. Applications include parts for engines and mechanical systems.

- AM60: A strong, ductile, well-castable alloy with good vibration-dampening properties. It is used in panels and seat frames for automobiles.

Copper Die-Casting Alloys

Overview of Copper Alloy for Die Casting

Cast copper comes in a wide range of alloys and is a versatile material. It is simple to cast, the metal is used in bushings and bearing sleeves, ship propellers, power plant water impellers, and plumbing fixtures.

Comparison Table of Casting Characteristics of Major Copper Casting Alloys

| LG2 | PB2 | |

| Tensile Strength (N/mm2) | 200-270 | 220-310 |

| Elongation (%) | 13-25 | 5-15 |

| Brinell Hardness | 65-75 | 75-110 |

| Density (g/cm3) | 8.5 | 8.8 |

| Freezing range (°C approx.) | 1010-854 | 1000-831 |

| Thermal Con (cal/cm2/cm/°C @ 25°C) | (71) | (45) |

| Electrical Con (% copper std. @ 20°C) | 15 | 9 |

| Machinability | E | G |

| Corrosion Resistance | E | E |

| Electro Plating Suitability | F | F |

| Non-Spark | Yes | Yes |

| Casting Characteristics – Sand | E | E |

| Casting Characteristics – Gravity | F | F |

| Casting Characteristics – High Pressure | U | U |

| Material Cost (pence/100 cc – July 1996) | 118 | 173 |

E = Excellent

G = Good

F = Fair

P = Poor

U = Unsuitable

Advantages and Disadvantages of Copper Alloy

Copper and copper alloys are among the most adaptable technical materials available. Copper is useful for a wide range of applications due to its combination of physical qualities, including strength, conductivity, corrosion resistance, machinability, and ductility.

Common Applications of Copper Alloy in Die Casting

Copper alloy casting produces components that are often found in wiring and electronics, as well as everyday kitchenware like pots and cutlery.

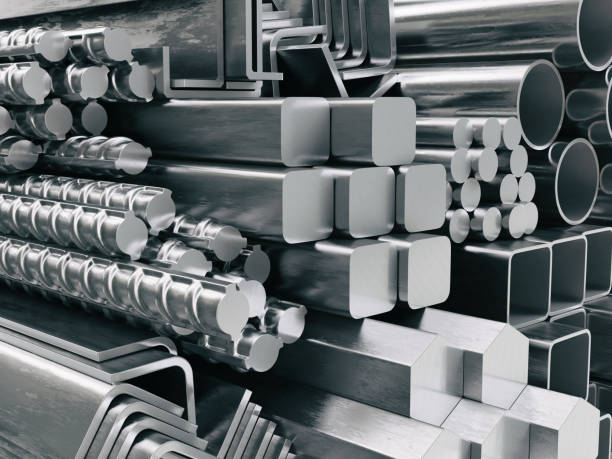

Steel Die-Casting Alloys

Overview of Steel Alloy for Die Casting

An alloy steel is a steel that is alloyed with more than one element. Alloying elements improve steel’s durability, hardness, corrosion resistance, and strength, resulting in more durable and solid steel.

Advantages and Disadvantages of Steel Alloy

This is an alloy steel that offers the properties you seek, regardless of whether your project calls for increased corrosion resistance, machinability, strength, or a variety of other qualities. Alloy steels can provide a variety of advantageous qualities with additional heat treatment, including

- Superior strength and hardness

- Improved corrosion resistance

- Increased hardenability

- Special alloyed characteristics

Common Applications of Steel Alloy in Die-Casting

Steel alloys can be formed into a variety of forms, such as pipes, tubes, plates, sheets, coils, bars, rods, and wires. They can also be made into forged fittings, buttweld fittings, flanges, fasteners, and other items. Industrial uses for steel alloys include the following:

- Automotive

- Mining

- Construction of roads

- Machinery

- Railroads

- Appliances

- Offshore work

- Buildings

Surface Finish and Aesthetics

Aluminum die castings can be finished in a variety of ways, but some are more popular than others because of their benefits. The typical finishing methods for aluminum casting are listed below for your reference.

Surface Finish Options for Different Die Casting Materials

- Anodizing

- Electroplating

- Chrome Plating

- Powder Coating

- Polishing

Cost Considerations in Die Casting

In general, die-casting is a low-cost production method. However, a number of things affect the price. Here are a few things to think about while choosing the most cost-effective solutions for your diecast project.

- Material Selection

- Production Cost

- Mold Cost

Material Cost Analysis for Different Die Casting Materials

Materials are a major factor in die casting cost since they affect the type of mold you can create, the die casting procedure to use, and the casted product’s quality. The cost is additionally affected by the unit price, part volume, material density, and weight of the material.

The material you use affects both the casting quality and the price of die casting. For example, due to its quality, aluminum is a preferred material for die casting. As a result, the cost of aluminum die casting is important.

Conclusion

There are many factors to consider during die-casting. The kind of die casting you need—pressure, structural, gravity, etc.—is not the most important. However, one of the most important selections you must make is the type of metal used for your die-cast.