Black Anodized aluminum paint is a prime example of how form and function can coexist perfectly in the world of surface finishes and coatings. This modern coating solution has made its way into various applications, from magnificent structures to consumer products, thanks to its distinctive combination of brilliant colors and exceptional durability.

In this article, we explore the global market of anodized aluminum paint, learning about its characteristics, advantages, and uses that have made it a popular choice across a range of sectors.

Anodized Aluminum Paint: An Overview

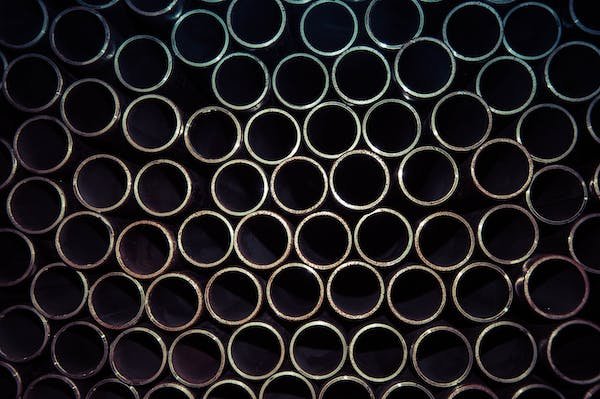

Anodization, an electrochemical process that converts aluminum’s surface into a protective oxide layer, creates anodized aluminum paint, a specialized coating method.

Anodized aluminum paint, in contrast to conventional paints, bonds molecularly with the metal, producing a tough and durable coating that provides both aesthetic appeal and protection.

Benefits and Characteristics

Durability: The extraordinary durability of anodized aluminum paint is one of its most notable benefits. Protection against abrasion, weathering, and corrosion is provided by the anodized coating. This makes it perfect for outdoor applications, where other types of finishes can frequently suffer from exposure to harsh weather factors.

Color Diversity: There is a wide selection of colors for anodized aluminum paint, from soft neutrals to strong, vivid hues. Due to their versatility, designers and architects are free to use their imagination to breathe life into a variety of projects.

Aesthetics: The anodizing technique gives the aluminum surface a distinctive aesthetic appeal. The metal will appear to have depth and texture thanks to the finish, which can range from matte to shiny.

Environmental friendliness: The low amount of trash that is produced during the anodization process makes anodized aluminum environmentally friendly. The coating procedure is environmentally friendly because it uses no volatile organic compounds (VOCs).

Low Maintenance: Anodized aluminum paint needs little care because it resists fading, flaking, and peeling. This asset is especially beneficial in busy areas or places that are difficult to visit for routine maintenance.

Applications of Black Anodized Aluminum

Architectural Design: A lot of architectural projects use anodized aluminum paint. It covers the exteriors of skyscrapers, improving their aesthetic appeal and offering defense against corrosion brought on by the elements and urban pollution.

Automotive Industry: The ability of anodized aluminum to produce distinctive and attractive finishes for automobile parts assists the automotive industry. To improve the car’s appearance and resist road conditions, anodizing can be applied to the wheels, trim, and accents.

Consumer electronics: Anodized aluminum paint gives devices like tablets, laptops, and smartphones a touch of class. The coating contributes to the gadgets’ sleek and contemporary style while shielding them from scuffs and abrasion.

Designing furniture and spaces: Anodized aluminum paint is a popular option for furniture and architectural applications due to its endurance and aesthetic potential. The coating may turn commonplace items like worktops and light fixtures into eye-catching focal points.

Why does corrosion happen between steel and anodized aluminum?

According to thermodynamics, aluminum is a reactive metal and should have a poor level of corrosion resistance. However, aluminum has a strong corrosion resistance because of a thin, compact layer of adhering aluminum oxide that coats the surface.

A surface film of aluminum oxide occurs instantly whenever a brand-new aluminum surface is produced and exposed to either air or water.

Some substances, particularly strong acids, and alkaline solutions, cause this aluminum oxide to dissolve. The metal corrodes quickly by uniform dissolution when the oxide coating is removed. There are several exceptions to the general rule that the oxide film is persistent throughout a pH range of roughly 4.0 to 9.0.

The surface film is insoluble in one of these settings, while weak points in the oxide film cause localized corrosion. Localized corrosion only occurs when aluminum is passive and protected by an oxide coating, such as the one created by anodizing.

Conclusion

Anodized aluminum paint stands out as a brilliant example of creativity in a world where aesthetics and effectiveness are valued equally. It is an attractive option for a variety of industries thanks to its capacity to combine brilliant colors, toughness, and environmental sustainability.

Anodized aluminum paint keeps expanding the potential of coating solutions, stretching the limits of both design and engineering, ranging from architectural wonders to commonplace appliances.