Definition

There are various casting processes, such as pressure die casting ,centrifugal, sand, investment, and gravity die-castings, among others. Many metals can be used for die casting, such as zinc, copper and magnesium, in this blog I will talk about aluminium die casting as an example.

Pressure aluminum die-casting (HPDC) including two kind of way , they are high pressure die casting and low pressure die casting .

The high pressure die casting is a die casting process in which molten aluminium is forced under pressure and high speed into a mold cavity. The mold is completely closed, sealed and held by a powerful press until the molten aluminium solidifies. The mold has a stationary and moving half; both halves are mounted to the casting machine’s plates.

Processes of high-pressure aluminium die-casting

The various processes involved in High pressure die casting:

• Mold preparation

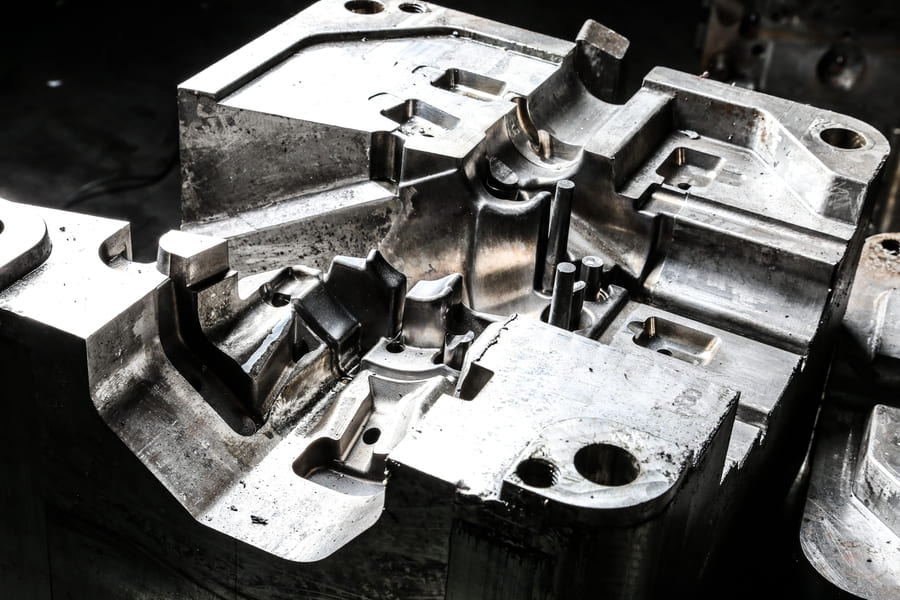

The mold is known as the tooling. The mold design determines the dimensions and contours of the casting . It affects the configuration, shape, uniformity, and quality of the castings.

So, before preparing the mold, you should consider the dimensions and geometry of the castings you want to manufacture. You should calculate the design of the mold according to the size of the casting.

Otherwise, the die can get damaged during the casting process.

To design the mold, you can use the 3D CAD/CAM systems. Computer-aided simulation calculation helps to optimally adapt the mold to the die-cast parts.

There are two halves in the mold, known as the cavity and core.

Always apply a lubricant to the interior walls of the mold. The lubricant regulates the mold’s temperature. It also creates a film between the molten metal and the mold.

• Holding the molds in the die-casting machine

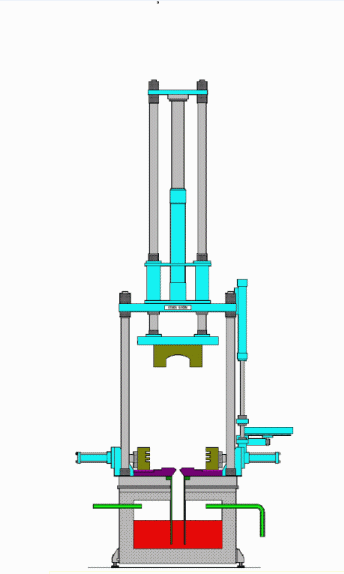

There have two kinds of die casting machine, one is hot chamber machine ,another is cold chamber machines .

we use more cold chamber in actual production. in this blog , we will use cold chamber machines as an example.

The machine has an injection end that uses hydraulics and pressurized gases to move the piston forward, thereby injecting the molten aluminium into the closed mold.

Also, the machine has a clamping end that uses hydraulics and mechanical toggles to absorb the injection pressure and hold the die shut while the casting solidifies.

This will enable the mold to withstand forces. The casting machine would keep the mold halves locked together during the die-casting process. It will prevent opening or springing back which may cause the liquid metal to squirt out.

Injection of the molten aluminium into the chamber

At this point, you would have to apply the molten aluminium to the die-casting machine.

The injection of the molten aluminium usually occurs within a fraction of a second. Once the mold cavity is filled, extremely high pressure is applied (usually over 1000 bar) into the molten aluminium through the injection plunger.

This pressure removes any gases trapped in the aluminium and feeds more aluminium into the mold. This partially compensates for shrinkage in the aluminium while it is solidifying.

The mold maintains the pressure until the molten aluminium has cooled and solidified.

There are two methods to do this, which are: The hot chamber system and the cold chamber system The clod chamber system is more common than the hot chamber system .

In hot-chamber die-casting, the aluminium would be heated within the mold cavity. On the other hand, in cold-chamber die casting, the aluminium would be heated in a completely separate furnace and then transferred into the casting machine.

The hot-chamber die-casting has a higher production rate than the cold-chamber die-casting.

Solidification of the die-casts

Before ejecting the die-cast from the mold, ensure the cavities’s metal solidifies . If the raw material is still in liquid form, you need to let it cool off before ejecting it.

Removal of the die casts

After solidification, you can now remove the die casts from the machine. but the die casts still with high temperatures,We have to borrow pliers to hold if you want to have a closer look for defects.

Thereafter, you need to apply the lubricant again on the internal surface before clamping the die together

CNC machining

This is to cut off any excess parts in the cast parts and make them more precise.

Good surface finish

This is the last stage of aluminum high pressure die castinig process (hpdc process ). The various surface treatment options you can use include: powder coating, chemical film, anodizing, etc.

Advantages of high-pressure aluminium die-casting

• High-pressure aluminium cast parts have high precision, optimum mechanical properties and excellent uniformity.

• HPDC is suitable to manufacture cast parts with thin walls. It manufactures cast parts with a wall thickness which can be as low as 1mm. It is therefore suitable to manufacture precise and lightweight castings.

• When compared to other casting methods, HPDC has a really short casting cycle. It solidifies in a split second. So, it is suitable to manufacture large-volume of identical aluminium cast parts.

• Although it has a high initial tooling cost, it is however cost-effective for large-scale castings. The reduced costs for bulk casting offset the initial tooling costs.

• High-pressure aluminium cast parts have close dimensional control and optimum surface finishing

Disadvantages of high-pressure aluminium die-casting

• HPDC requires high initial tooling costs and complex/expensive equipment. It is generally an expensive method of casting. so, it is not suitable for small-scale die-casting where the initial tooling costs can not be offset by the quantity of production.

Even for large-scale castings, although you can repeatedly use the mold, if the mold design is too intricate, continuous maintenance will reduce its lifespan.

• High-pressure aluminium die-castings are susceptible to porosity. After pouring the molten metal into the mold, if the air is not properly evacuated and it gets trapped in the casting, this can cause porosity.

Because heat treatment is difficult in HPDC, its castings usually suffer from porosity. This negatively impairs the appearance and integrity of the castings.

• The weight of the aluminium die-castings is limited by the locking force of the high-pressure machine.

Application of high-pressure aluminium die-cast parts

• In the medical sector,

the cast parts are used to manufacture hospital beds, diagnostics equipment, ultrasound system, dialysis equipment, surgical lamp base, monitoring device, etc.

• In the Industrial sector.

They are used to manufacture industrial machinery, such as rotors and stators, impellers, shaft sleeves, valves, etc.

• In the military sector,

They are used in the production of ammunition, such as trigger guards and Remington receivers.

• In the renewable energy sector,

They are used to produce power generation and distribution components, such as solar panel brackets, wind turbine parts, etc.

• In the aerospace sector

You can use them to manufacture fuel system parts, electronic enclosure detentions, engine piston heads, ring parts, seat components, airline handrails, engine housings, window frames, valves, mounts, engine rings and engine blades.

• In the automotive sector

You can use them to manufacture rack housing, chain cover, transmission housings, steering gear housings, clutch housings, carburettor housings, valve covers, wheel hubs, stepper motors, shade poles, heat sinks, stators, alternator housings, etc.

Furthermore,

you can use these castings to manufacture some components of electric vehicles, such as heat sinks, gearboxes, intake tubes, car rims, engine cylinder heads, etc

• In the telecommunications industry,

You can use them to manufacture telecommunications equipment such as base plates, heat sinks, etc. They are also used to manufacture various networking equipment. These include aluminium cast RF filter boxes in base stations, shielding boxes for microwaves, heat sinks, connector housings, etc.

• In the power sector,

you can use these castings to create a cylinder head, cover, cylinder block, crankcase, piston, pump body, pump cover, generator housing, engine gear chamber, etc.

• In the electrical/electronic industry,

you can use the castings to manufacture RF filler repeaters, tower housings, electrical meters, LED modules, etc.

• In the construction industry,

they are used in building large structures such as window frames, building frames, superstructures, bridges, etc. woL

Low pressure die casting

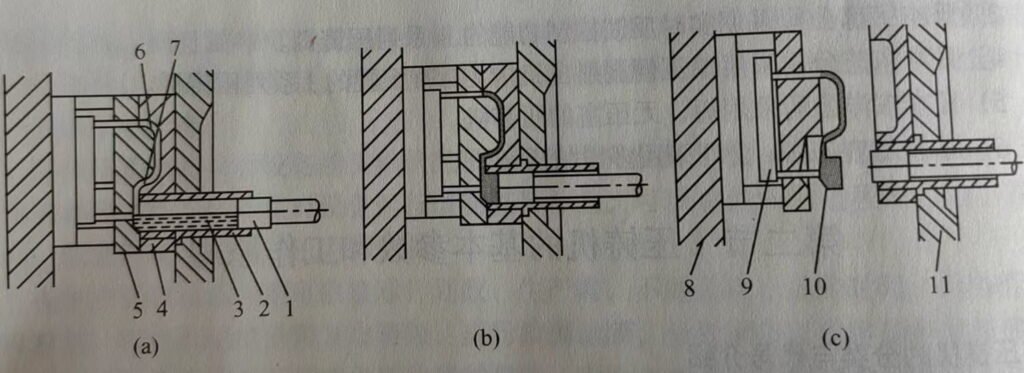

Die casting process

In the sealed crucible/tank, dry compressed air is introduced and the metal liquid rises along the riser tube into the straight sprue. The gas pressure on the liquid surface is released and the unconsolidated liquid flows back into the crucible. The mould is then opened and the casting removed.

Advantages of low pressure aluminium die-casting

This casting method has good shrinkage, dense castings, easy casting of large, thin-walled and complex castings, no risers and a metal yield of 95%. No pollution, easy to achieve automation.

Disdvantages of low pressure aluminium die-casting

However, the equipment costs are high and the production efficiency is low. Generally used for casting non-ferrous alloys.