Various industries use die-casting in their manufacturing process. These include the electrical, automotive, aerospace, marine, and telecommunications industries.

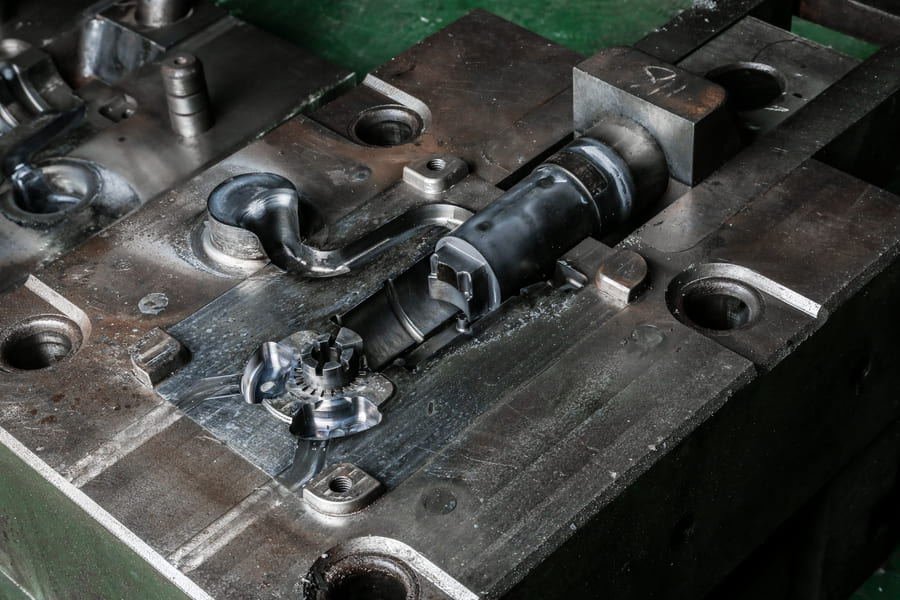

Die cast, also called pressure casting, is a process whereby solid metals are melted to a molten state at the desired temperature and then injected under high pressure into a mold cavity with proper size and shape. Thereafter, it will be allowed to cool.

Die casting is an expensive production process. So, you may be wondering why die-casting is so costly. Right? In this article, we will explain the various factors why die casting is expensive.

Follow closely.

Why Die Casting is Expensive

- Material Cost

The raw material cost is an important factor in assessing the aggregate cost of a die-cast. The materials determine the choice of mold produced, the casting quality, and the die-casting process used.

Non-ferrous alloy materials are commonly used in the die-casting process due to their impressive properties. They are one of the most optimal materials for die-casting various lightweight parts.

They are highly malleable and softer than ferrous metals. Because they have low iron content, they are corrosion-resistant. They are also easy to fabricate.

Despite being expensive, aluminium is widely used in die casting. It costs almost $3000 per ton. Also, the aluminium electrical melting furnace used in the melting process costs an average of $2500. All these contribute to the expensive nature of die-cast.

- Production Cost

Two factors are responsible for a high production cost: the machine type and the labour cost. Production cost is calculated based on the hours spent and the number of cycles.

Two types of die-casting machines are used in the manufacturing process—the hot and cold chamber die-casting machines. The main difference between both depends on where the container houses the molten metal. For the hot chamber, the container is located inside the machine, while for the latter, the container is placed outside.

The cold chamber casting machine is preferred during the casting process because it works with metals with high melting temperatures, and it is typically expensive compared to hot chamber machines due to its sophistication.

An average cold chamber machine costs $20,000 – $100,000, depending on the size and quality. The complexity accounts for the extra step that makes it more expensive, which increases the production cost. Note that:

- The cold chamber machines increase the time spent on production casting by 50-90 times per hour.

- Production level is slow since cooling occurs before injection of the molten metal.

- The molten metal undergoes oxidation which requires surface finishing (extra cost).

Moreover, die-casts are used for large production, which would require a machine with a large clamping force. Also, for high flow, materials would further need a tonnage machine. Therefore extra costs are incurred in the production process.

Other machines needed include CNC machines, tumbling machines, etc.

- Tooling Cost

There is a high tooling cost involved in die casting. As noted earlier, the machines used in this process include hot and cold chamber machines, CNC machines, tumbling machines, etc. These machines and equipment are expensive.

- Performance Specification

A high design requires a high dimensional tolerance for production. Die casting alloy materials have limitations when it comes to the design of components of high-strength materials.

This brings the need to add certain design strengthening features such as gussets and ribs before enlarging the thickness of the wall. An average unit of gusset costs $10 and ribs $92.

The added strengthening features would assist the die casting alloy meet up to the performance specification requirements for the design, but this results in an increased cost in the production process of the added features.

- Mold Cost

The mold is the container in which the molten metal is injected. Its design, which varies on the material being designed, makes it expensive. Even with a simpler design, molds are expensive.

For complex products, high-end machines such as CNC machining are used to obtain accurate, precise, and quality designs. This costs an average of $11000 – $19,000 for commercial usage and as much as $100,000 – $150,000 for industrial use.

Furthermore, the number of cavities required in the mold for producing different designs also contributes to the mold cost. The overall cost can go up to millions of dollars depending on the number of cavities used.

Other factors that lead to the expensive nature of die-cast are:

- Cost of Utilities ( Electricity, water, and gas): The die-casting machines consume lots of electricity to operate the pressure pumps. An average die-casting machine consumes 455 KJ of electricity. It is advisable to have a power plant to run it.

- Fixed costs and Overhead Costs such as rent, insurance, salaries, and medical benefits.

- Labour rates and the Number of Labor Hours: Other than the actual production processes, die casting also includes processes such as packaging, inspection, and processing. All these secondary processes have to be accounted for in the production cost.

- Value-added Process: These are processes that occur outside the plant but are included in the total cost of production, such as surface finishing, changing the cast product from a raw state to its completed form, maintenance of machines, and coating, among others, are quite costly. These are all typical values of added costs in the production process that makes the outcome expensive.

Note that die-cast operation costs can be cost-effectively managed in the following ways:

-Using some cast parts to design others.

•Also, other features can be incorporated into the production process to do away with assembly operations. These features include swaging, riveting, machine screwing, welding, and stamping.

Is die casting really expensive?

At this point, we need to consider if die cast is actually expensive. Yes, die casting requires high tooling costs for procuring the needed sophisticated machines and tooling.

However, these initial costs can be offset by the reduced production cost in large-scale production. This is because you can repeatedly use the mold to manufacture lots of casting. So, die casting is not expensive for large-scale casting.

Conversely, in small-scale die casting, there might be no need for repeatedly using the mold. So, we can admit that die casting is expensive.

Does die casting worth its cost?

Even with its high production cost, die casting has outweighing advantages. These include:

• It allows you to create very complex and intricate components and parts.

• Die casting Provides options for different thicknesses of the wall, e.g., thinner waller thickness.

• Tighter dimensional accuracy/tolerances.

• The material used in the die-cast process can be recycled.

• Manufacture various parts without the need for assembly.

• It offers fast production cycle times.

• Suitable for the production of parts on a large scale.

• The final product comes in a pure form with no gas trapped inside the metal.

Thus, die casting is worth its cost.

Conclusion

In this article, we have taken you through the various reasons why die casting is expensive. These reasons include material cost, tooling cost, production cost, etc. We also considered whether die casting is truly worth it. This knowledge will help you understand pricing in the die casting industry.